Enhancing CIP System Efficiency for Coffee Extraction Tanks with Pressure-Open Nozzles

Solutions or Products Featured

in This Case Study

A beverage factory was experiencing challenges in cleaning its fruit juice blending tanks.

The tank cleaning nozzles in use were not functioning effectively, forcing operators to perform manual cleaning under time pressure before starting the next batch.

The factory has 40 tanks, each of which needed to be cleaned once every three days.

Manual cleaning took about 10 minutes per tank, resulting in an average of four hours of labor per day.

To reduce the burden of this cleaning process, the customer consulted IKEUCHI about upgrading the existing tank cleaning nozzles.

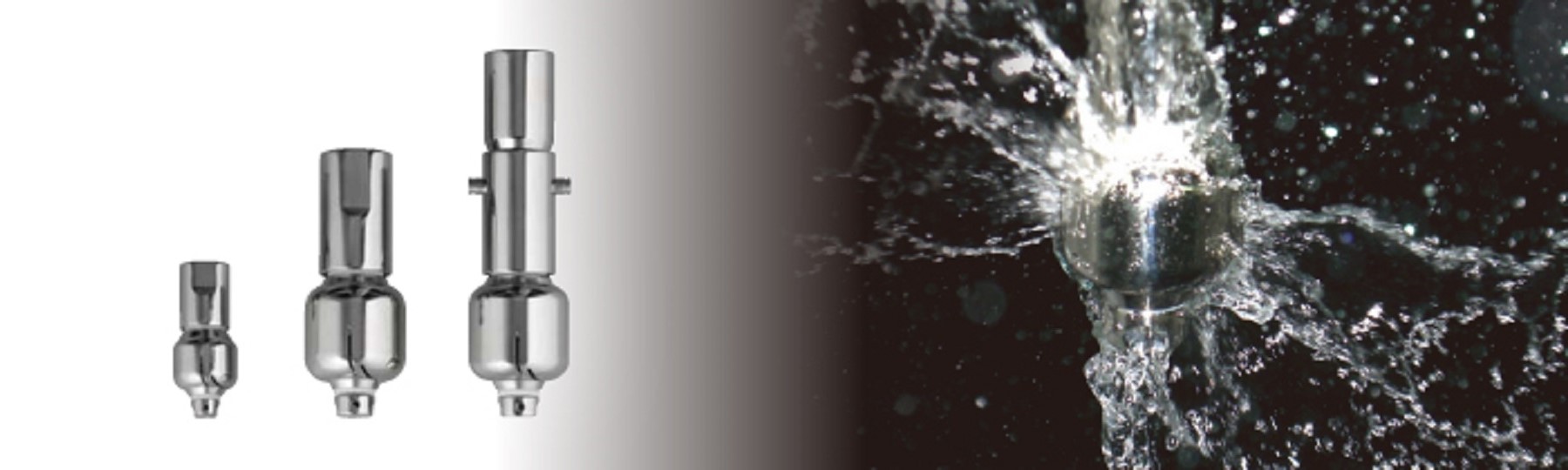

Upon hearing from the customer, we identified the “ES” series as the most suitable solution to address the challenge. These nozzles deliver a flat-fan spray while rotating horizontally, enabling thorough cleaning of the tank’s interior surfaces.

(The ES series is available in three spray coverage patterns: 360 degrees, upward 180 degrees, and downward 180 degrees.)

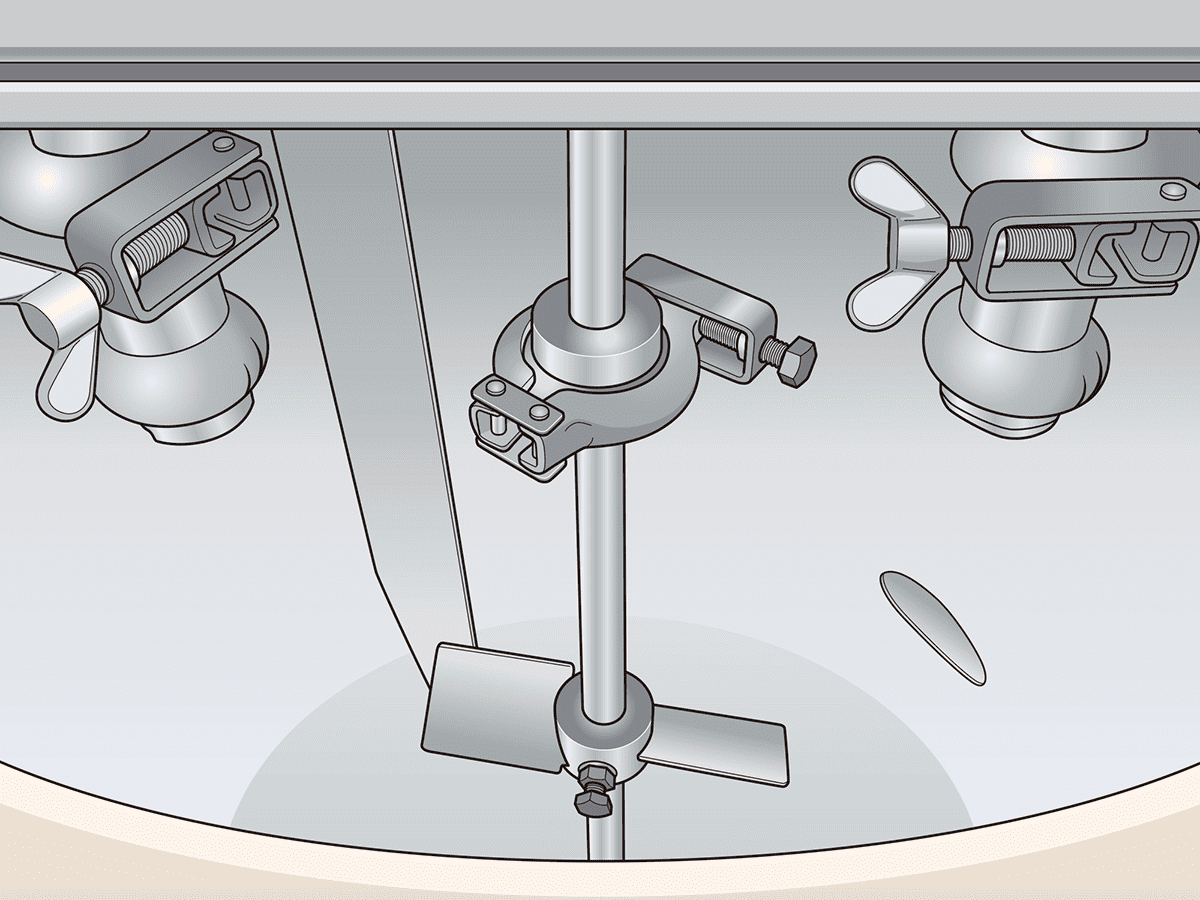

During the site visit, we inspected both the tank interior and the existing nozzle, discovering that the nozzle had been installed at an improper height. Raw materials entering through the side-mounted inlet were interfering with it—causing buildup and making it prone to clogging.

To resolve this, our first recommendation was to mount the “ES” nozzle at a higher position than the material inlet.

As a further finding, it became clear that a single nozzle was insufficient to clean the entire tank interior, prompting us to propose a two-nozzle configuration that offsets each blind spot.