Tire Manufacturing | Odor Control Using Clog-Resistant, Easy-to-Maintain Spray Nozzles

Solutions or Products Featured

in This Case Study

Supporting labor savings and consistent quality across diverse industrial sectors—including steelmaking, power generation, automotive, and electronics—IKUECHI’s spray nozzles might not be the first thing associated with livestock applications.

Yet they have also proven highly effective in the livestock industry. This case highlights their implementation at a poultry farm.

In recent years, many poultry houses have adopted tunnel ventilation systems as a countermeasure against high summer temperatures. These systems create a forced airflow inside the house, providing both cooling and ventilation.

How It Works:

Fresh outside air is drawn in through inlets or cooling pads located on the intake side, while large fans installed in the opposite wall or roof powerfully pull the inside air out of the house, thereby creating a strong airflow.

The air moves unidirectionally along the length of the poultry house, and the resulting increase in wind speed produces a wind-chill effect that lowers the birds’ perceived temperature.

Front view of the poultry house—intake openings visible

Rear view of the poultry house—multiple large exhaust fans powerfully pull air out of the house

At a large poultry farm equipped with a tunnel ventilation system, controlling odors generated by the poultry house exhaust air had become a significant challenge.

Dry dust from chicken manure and odor-laden feathers inside the poultry house were drawn toward the exhaust side and passing through the ventilation fans, sometimes escaped outdoors, causing foul odors to spread to the surrounding area.

Exhaust fan outlet (image)—odor-laden feathers drifting and dust accumulating on the floor

These foul odors frequently prompted complaints from nearby residents, and ongoing complaints sometimes led to improvement orders from local authorities.

In the worst-case scenario, if corrective measures failed, the farm could even face an operational shutdown order .

Since living animals are being raised, operations cannot simply be halted. Approaches such as deodorizing agents, however, carried the burden of high running costs, creating challenges for sustainable implementation.

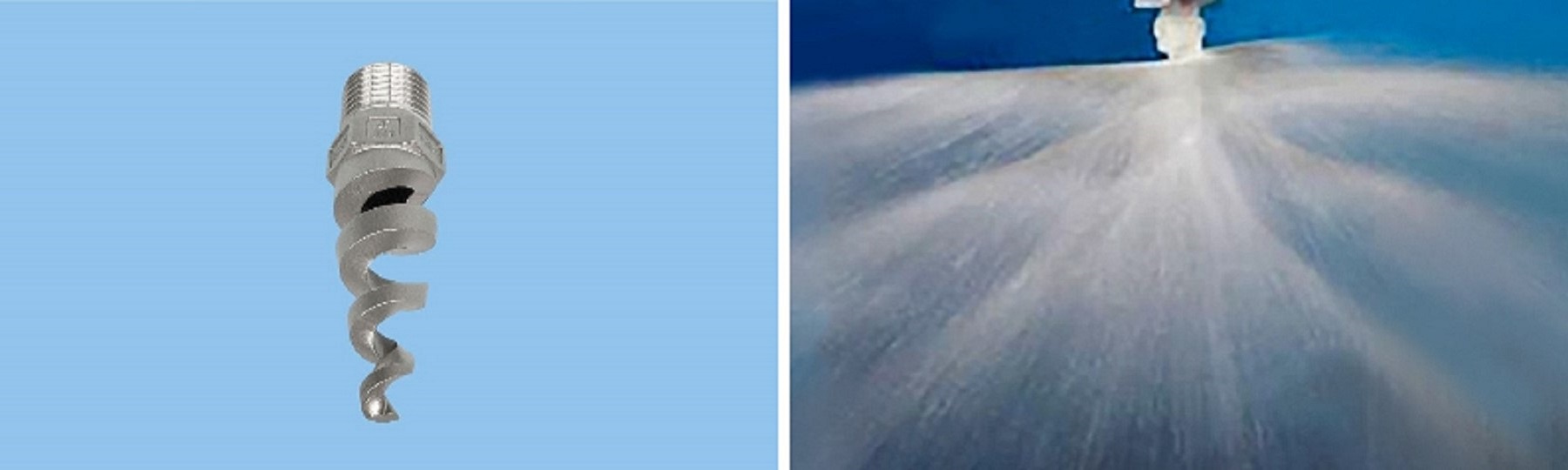

We proposed installing spray nozzles in the space downstream of the exhaust fans to wash down dust and feathers from above. For this application, IKEUCHI’s spiral nozzle UZUJP Series provides an optimal solution.

Features of the UZUJP Series:

Mounted at a height of 2.5 meters, this nozzle provides uniform coverage over a circular area with a diameter of 6 meters, allowing two nozzles to cover the entire exhaust space of one poultry house.

Delivering outstanding performance at a relatively low cost makes the UZUJP Series ideal for water spraying in poultry houses.

In testing, intermittent spraying for 15 seconds every 10 minutes proved highly effective. As a result, full-scale implementation across all poultry houses in the farm was approved, and actual operation has since suppressed the spread of foul odors.

Today, the deployment of our nozzles is steadily expanding to other farms operated by the group companies.

IKEUCHI’s spray nozzles continue to support the stable operation of poultry farms every day.