Shower Balls for Effective Cleaning of Purified Water Storage Tank in Pharmaceutical Plants

Note: The product used in this case is a custom version of the SWB Series, as detailed in the following article.

Solutions or Products Featured

in This Case Study

A sanitary tank is a highly hygienic vessel used in manufacturing processes for pharmaceuticals and food products. It is employed for storing, mixing, heating, cooling, reacting, and preparing liquids.

To maintain a high level of cleanliness, material selection and structural design must meet strict sanitary management standards.

A tank head is the curved section located at the upper and lower ends of a tank. It is generally formed in a hemispherical or elliptical shape to enhance resistance to internal pressure.

The upper tank head is typically equipped with openings for a manhole, piping and valve connections, and instrumentation fittings.

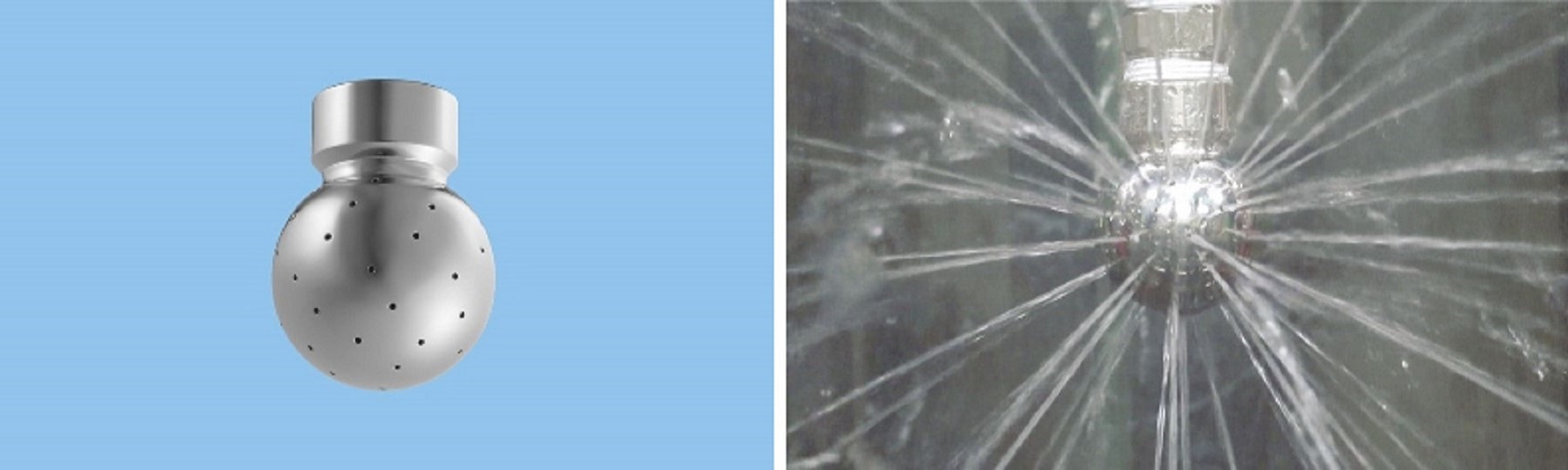

In general tank cleaning applications, two main types of nozzles are commonly employed: rotating nozzles that clean the inner surfaces of tanks by rotating their heads in two or three dimensions, and shower ball nozzles, which are non-rotating nozzles that discharge cleaning liquid as multiple radial jets from radially arranged holes.

From left: 2D rotating nozzle, 3D rotating nozzle, shower ball nozzle

In pharmaceutical manufacturing, complete cleaning of the entire tank interior is mandatory. Given the structural risk of rotation failure, rotating nozzles are seldom employed, making shower ball nozzles the sole viable choice.

A tank manufacturer undertook the production of a large sanitary tank for a pharmaceutical plant.

Upon reviewing the user’s instructions during specification preparation, it became clear that fixed cleaning nozzles, not rotating ones, were required.

The instructions further required that, to ensure thorough cleaning, the spray be precisely directed onto the inner surface of the upper tank head around and behind the manholes, connection ports, and instrument fittings.

Although the manufacturer was capable of designing shower ball nozzles with spray holes arranged uniformly over a spherical surface, they had no design experience with nozzles for targeted cleaning inside the tank, leading them to consult IKEUCHI, a specialist in spray nozzles.

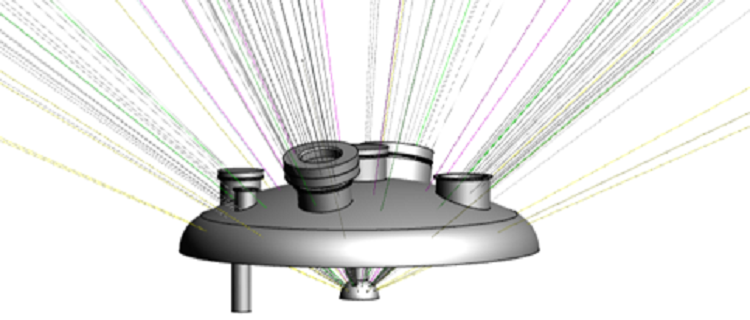

After receiving the tank specifications and 3D drawings from the manufacturer, we promptly verified the required cleaning flow rates and pressures, determining the mounting positions for the shower ball nozzles.

We then created spray trajectory diagrams based on these target areas while carefully reviewing the positions and required number of spray holes.

After completing the design, we produced a prototype using a 3D printer and proceeded to a series of cleaning tests. Together with the tank manufacturer, we conducted repeated testing to identify and eliminate any issues.

This close collaboration, founded on mutual trust between the two companies, became a key driving force that propelled the project forward.

After several rounds of verification testing and prototyping, we confirmed that all blind spots within the tank could be cleaned reliably.

Following the fabrication of the final shower ball nozzles, full-scale testing on the plant tanks was successfully completed, leading to their official adoption.

IKEUCHI’s shower ball nozzles for tank cleaning continue to support high-quality pharmaceutical manufacturing by ensuring thorough cleaning of tanks that must meet stringent sanitary standards.