Preventing Static Electricity with Humidification: A Guide | Anti-Static Solutions | Industrial ESD Prevention | ESD Elimination with Humidity

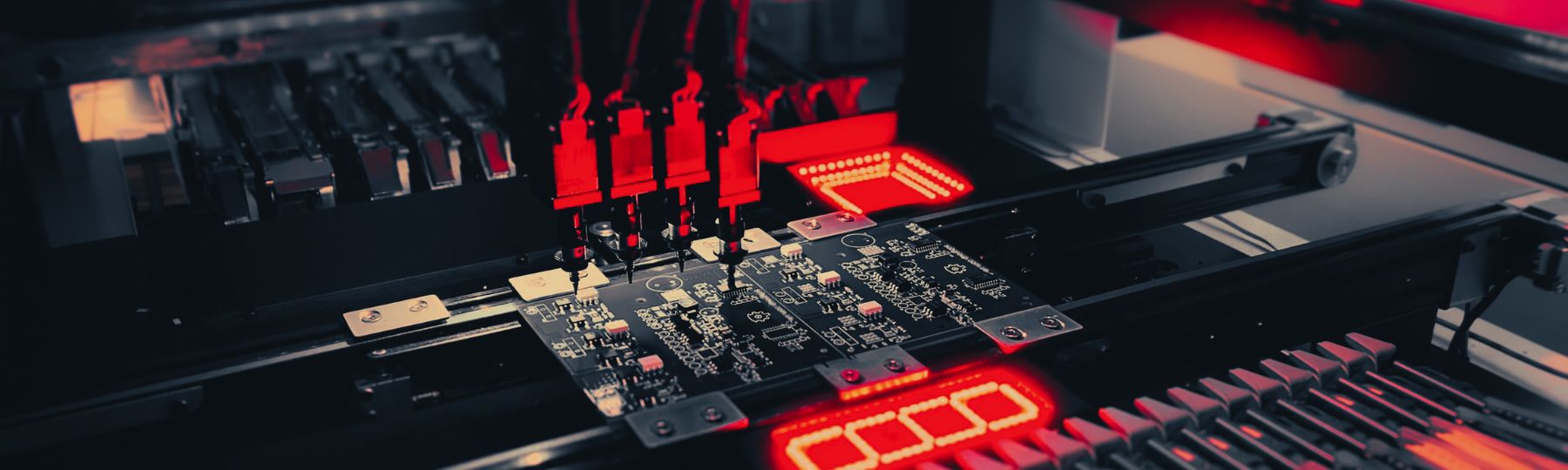

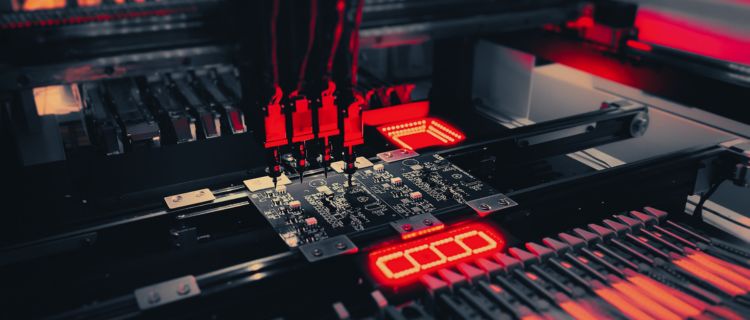

In the realm of modern electronics manufacturing, Surface Mount Technology (SMT) has revolutionized the production of electronic assemblies, offering efficiency, precision, and miniaturization. SMT involves the intricate process of placing surface mount components onto printed circuit boards (PCBs), a crucial step in creating electronic devices. Central to this process is the utilization of quality nozzles and a precise humidification system. Quality nozzles are fundamental in the wet process. Meanwhile, a well-controlled humidification system plays a pivotal role in the assembly process. This maintains an optimal environment within the manufacturing facility, safeguarding sensitive electronic components from static electricity and preventing issues such as component misalignment or damage due to electrostatic discharge (ESD). In this context, understanding the significance of employing superior nozzles and an effective humidification system is paramount for achieving high-quality, reliable electronic products in SMT manufacturing.

Humidification for assembly process- Surface Mount Technology (SMT) is a method used in the electronics industry to assemble electronic circuits. See below image of steps.

Some issues faced in SMT manufacturing with a lack of humidity, are soldering defects, circuit damage, bad mounts, dust adhesion, etc. AKIMist® E is a complete dry fog humidification system that delivers optimal humidification levels for your facility to prevent these complications and increase efficiency & productivity.