Article by Industry: Electronics | ESD Prevention with Dry Fog | Optimal SMT Manufacturing Environment

When we think about humidity control in electronics manufacturing, we typically focus on avoiding immediate threats: static discharge, soldering defects, or assembly errors. But what’s less often discussed is how managing humidity during production can have a long-lasting impact on the performance, durability, and lifespan of electronic devices out in the real world.

In an era of shrinking device sizes and increasing complexity, even microscopic environmental factors during production can ripple into major reliability issues later, making humidity one of the most underestimated players in electronics longevity.

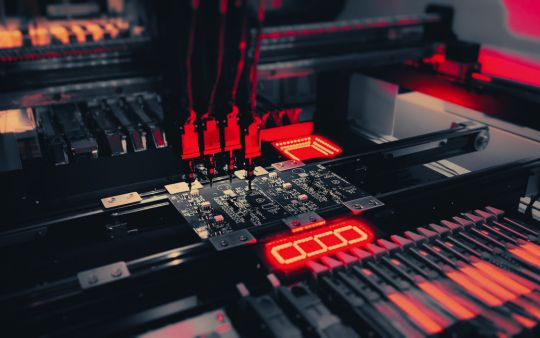

Modern electronic components are more sensitive than ever. Moisture-sensitive devices (MSDs), such as BGAs, ICs, and fine-pitch components, can absorb water vapor from the air, which gets trapped inside the packaging or under conformal coatings. During soldering or thermal cycling, this can expand rapidly, leading to:

While these defects may not cause immediate failure, they significantly reduce product lifespan, leading to warranty claims, customer dissatisfaction, and e-waste.

Research shows that even minor humidity fluctuations during assembly and packaging can weaken the long-term performance of electronics. For example:

This is where precision humidity management plays a quiet but critical role.

Unlike traditional humidification systems, dry fog technology introduces ultra-fine droplets that evaporate instantly, increasing relative humidity without wetting surfaces or sensitive components. Its advantages in electronics manufacturing include:

By creating a controlled microclimate, dry fog systems help manufacturers go beyond immediate defect prevention; they help future-proof devices.

Improving humidity control doesn’t just protect individual devices, it reduces the number of products that fail prematurely, supporting a more circular and sustainable electronics economy. Fewer warranty returns, fewer replacements, and less discarded hardware ultimately mean a lighter environmental footprint.

Electronics manufacturers aiming for next-level quality and sustainability should think of humidity not just as a factory-floor concern, but as a long-term investment in product reliability. With advanced solutions like dry fog, it’s possible to create manufacturing environments that protect sensitive components from the inside out, giving your products the best chance to thrive in the field.