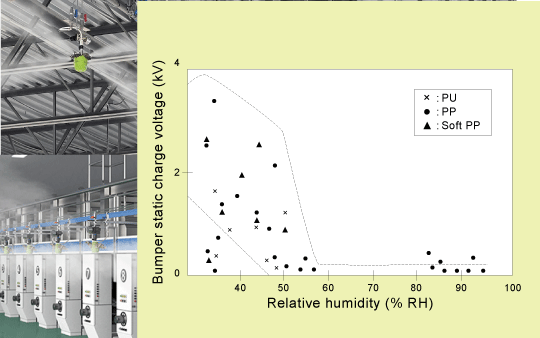

Absolute and Relative Humidity: The Relationship with Static Charge

For electronics manufacturers, maintaining consistent yield and quality on surface-mount technology (SMT) lines can feel like walking a tightrope, especially during seasonal shifts. Winter months often bring dry indoor air, which can lead to a subtle but significant challenge, static electricity buildup.

Low humidity environments, typically below 45% relative humidity at 68°F (20°C), can create conditions where static charges accumulate rapidly on sensitive components. In SMT processes, this can manifest as

These challenges are not new, but their impact grows as boards become more complex and components more densely packed. Recognizing and mitigating environmental factors is critical to maintaining throughput and quality.

One effective strategy for managing static is the use of precision dry fog humidification, such as Ikeuchi’s AKIMist®E system. Unlike conventional humidifiers, dry fog delivers ultrafine droplets that mix uniformly into the airflow without wetting surfaces or creating condensation. This provides several operational advantages

These benefits make dry fog humidification particularly useful during seasonal swings when indoor humidity can drop rapidly and unpredictably.

To maximize the benefits of environmental control, consider the following

1. Continuous humidity monitoring: Deploy sensors at multiple points across the production floor to track relative humidity in real-time.

2. Targeted intervention: Focus humidification on areas with high-density boards or sensitive placement zones rather than broad, uniform application.

3. Regular system checks: Even precision systems can experience nozzle clogging or pressure drops over time. Scheduled inspection ensures consistent performance.

By combining monitoring with precision humidification, manufacturers can mitigate the seasonal effects of dry air and reduce the operational impact of static.

As SMT technology evolves, operational challenges like static and environmental variability will only become more critical. Addressing these factors proactively through targeted humidity control and informed monitoring supports consistent yield, compliance with stringent standards, and smoother production during seasonal swings.