Article by Industry: Automotive | Controlled Environment Manufacturing | Dry Fog Dust Suppression

In business operations, countless factors demand attention—but often, the unseen elements are the most overlooked. Consider a commercial print facility that invests heavily in premium-grade equipment to ensure a high-quality end product. While this investment is crucial, the surrounding environment where this equipment operates can significantly impact success. For instance, maintaining proper humidity levels is essential to prevent ESD (electrostatic discharge) and eliminate static-related issues. The need for humidity control spans industries, each with its unique applications and requirements. In this article, we’ll delve into the role of humidity control across various industries and explore the optimal levels for maximum effectiveness.

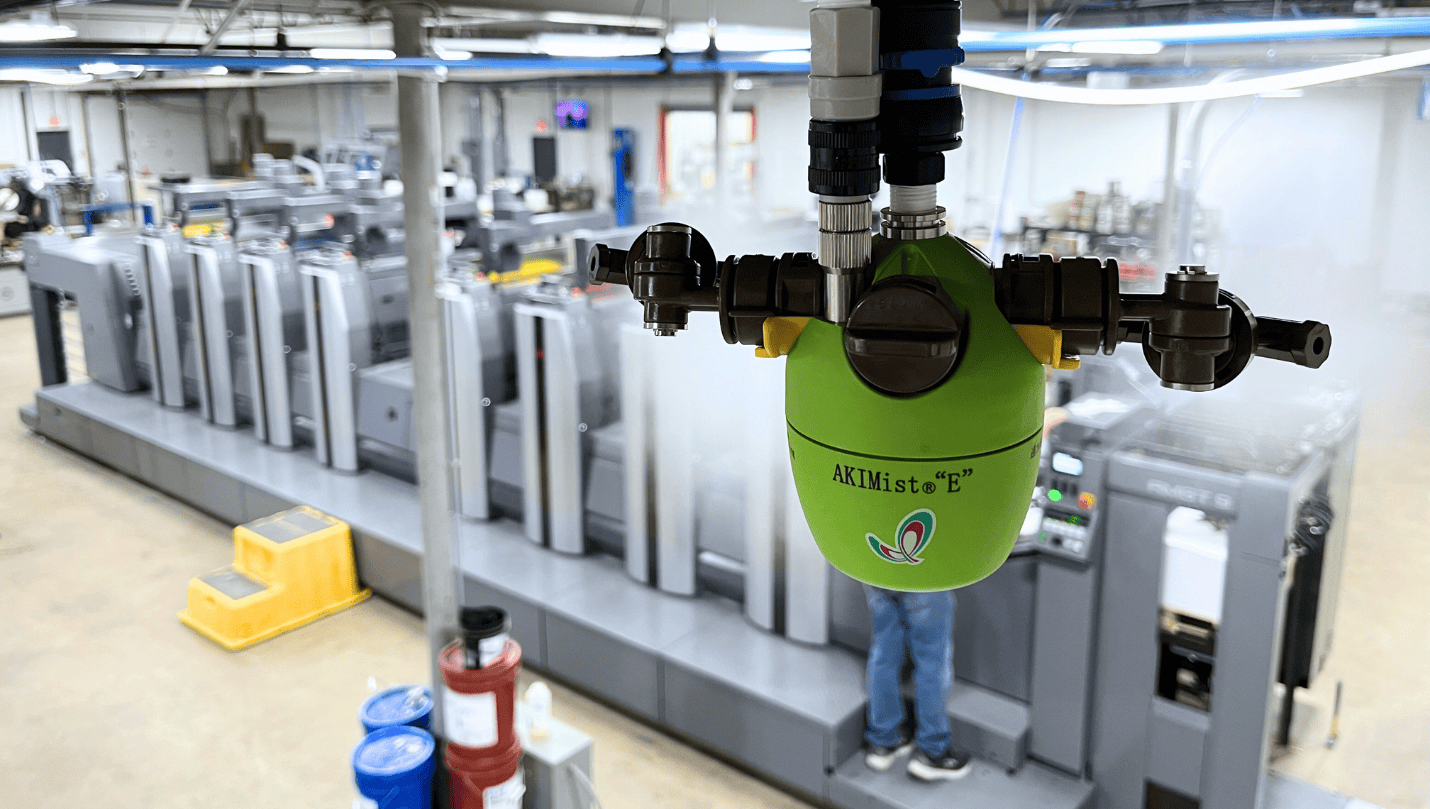

The commercial print world thrives on precision. Static electricity, caused by low humidity levels, can lead to paper misfeeds, jams, and even damage to sensitive equipment. High-end printers often require humidity levels between 40% and 60% RH (relative humidity) to ensure smooth paper handling and ink adherence. By maintaining optimal humidity, print facilities can prevent costly disruptions, improve print quality, and extend the lifespan of their machinery.

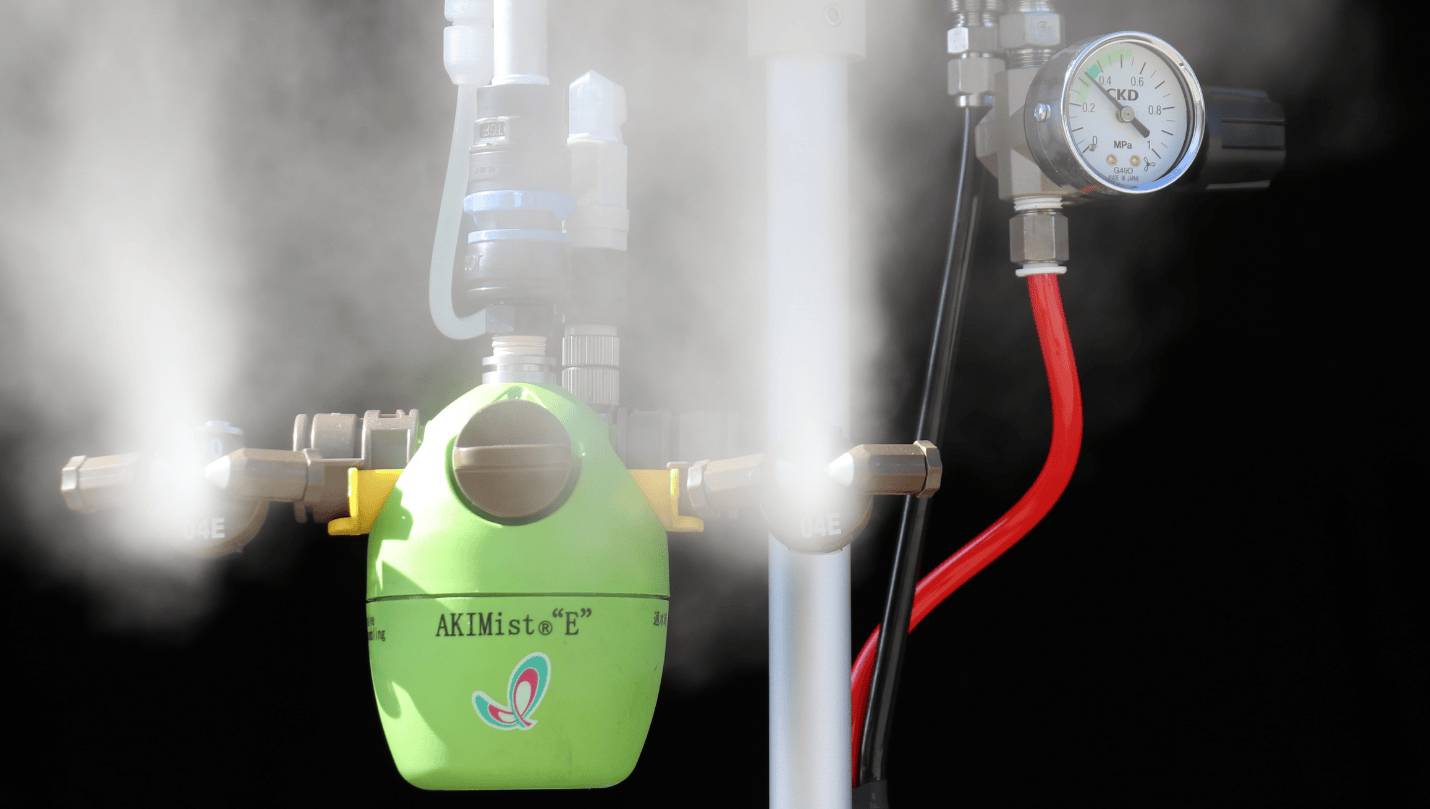

Check out what our customers have to say: Print Solutions with AKIMist®E: Numerix Testimonial

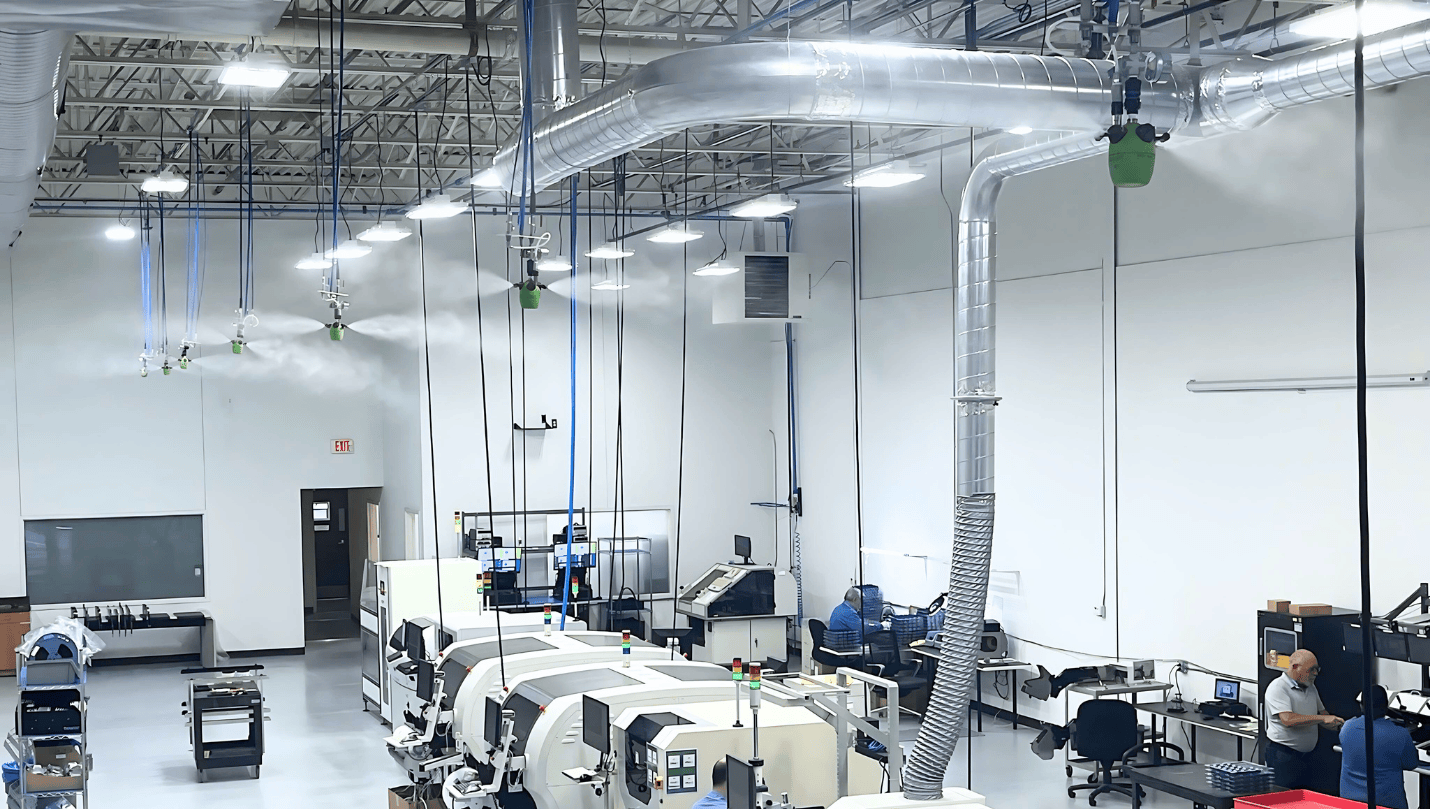

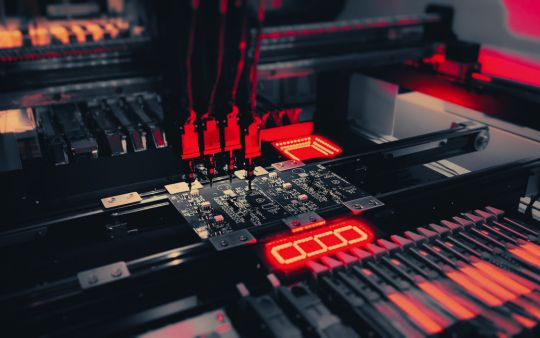

Surface Mount Technology (SMT) manufacturing in the electronics industry demands a meticulously controlled environment. Static discharge, even at low levels, can damage sensitive components and compromise entire production runs. To mitigate these risks, humidity levels in SMT facilities are typically kept at 40% to 50% RH. Controlled humidity not only prevents ESD but also reduces the risk of solder paste drying out prematurely, ensuring a seamless manufacturing process.

More on the electronics industry: Article by Industry: Electronics

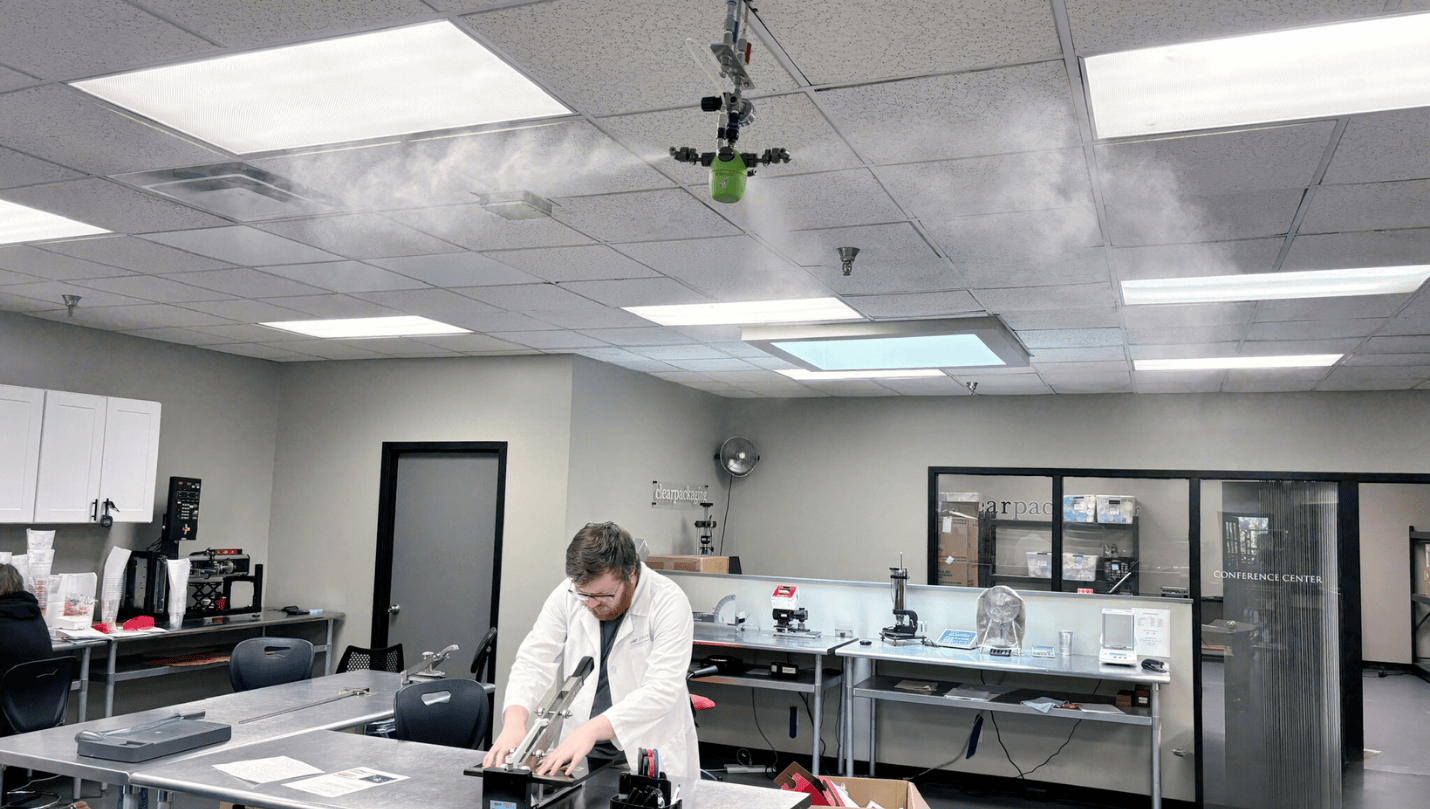

From pharmaceuticals to electronics, testing laboratories depend on consistent environmental conditions for accurate results. Humidity fluctuations can skew measurements, damage sensitive equipment, and affect sample integrity. Ideal humidity levels vary depending on the application, but many labs maintain levels between 40% and 55% RH. Precision humidity control systems help laboratories meet regulatory standards and ensure reliable outcomes.

Check out what our customers have to say: Clear Packaging Case Study

Humidity control is essential in controlled-environment agriculture (CEA), including indoor farming and greenhouses. For crops like leafy greens, tomatoes, herbs, or even perennials, optimal humidity ensures proper transpiration, nutrient uptake, and growth. Typically, humidity levels between 50% and 70% RH are ideal, depending on the crop. Advanced humidity systems also help prevent the spread of pests and diseases, creating a more sustainable and profitable operation.

Check out what our customers have to say: Walter’s Gardens Testimonial

Cannabis cultivation requires precise environmental control at every stage of the plant’s life cycle. During the vegetative stage, humidity levels of 65% to 70% RH promote vigorous growth. In the flowering stage, reducing humidity to 40% to 50% RH prevents mold and mildew while encouraging resin production. Modern growers use automated humidity systems to fine-tune these levels, maximizing yield and potency.

More on Cannabis cultivation: Humidity Control in Cannabis Cultivation

Mushrooms typically thrive in high-humidity environments, where moisture plays a pivotal role in their growth. For successful cultivation, humidity levels are often maintained between 85% and 95% RH. Insufficient humidity can result in dry, stunted mushrooms, while overly humid conditions can encourage mold and bacterial growth. Humidity control systems ensure the perfect balance, fostering healthy yields and consistent quality.

More on mushroom cultivation: Mushrooms Have Needs Too

Ikeuchi USA authorized distributor for mushroom applications: Techmark

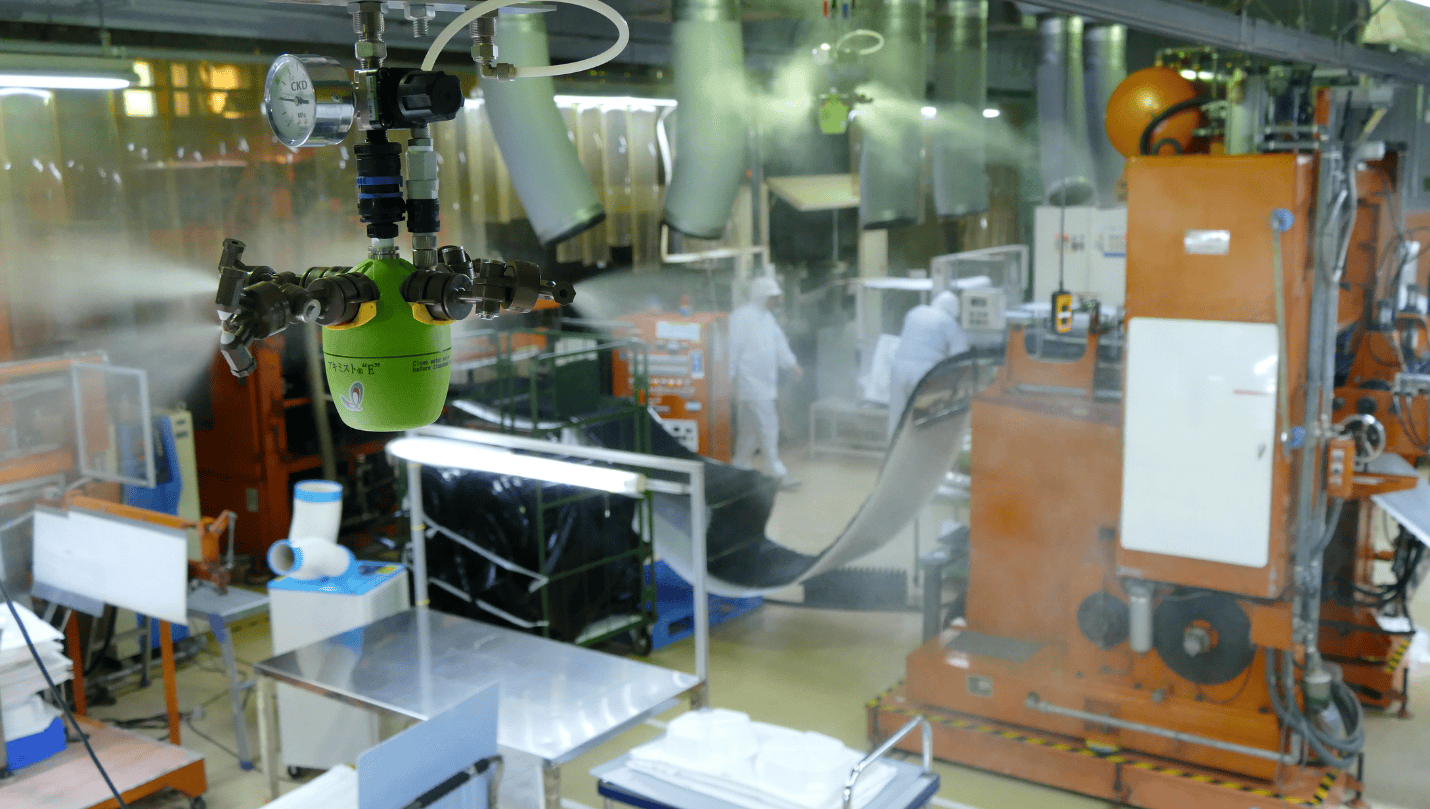

Humidity control is critical in the food and beverage industry, where product quality, safety, and shelf life are paramount. In food processing facilities, maintaining humidity levels between 50% and 60% RH prevents moisture loss, which can lead to weight reduction and spoilage. For example, baked goods require specific humidity levels to retain freshness, while dry goods like powders or grains need controlled environments to avoid clumping or contamination.

In beverage manufacturing, especially in breweries and wineries, humidity regulation helps prevent condensation on equipment, which could introduce unwanted microbial growth or affect packaging integrity. By implementing robust humidity control systems, facilities can maintain compliance with food safety standards, reduce waste, and ensure consistent product quality for consumers.

More on food packaging applications: Packaging Leaflet / Case Study

More on baking applications: Food for Thought: Baking Edition

Humidity control is more than a background consideration—it’s a vital component of operational success. Whether you’re in commercial printing, electronics manufacturing, or agriculture, maintaining the right moisture balance can be the difference between thriving and struggling. By investing in tailored humidity solutions, businesses can safeguard their processes, maximize their output, and secure long-term growth

Ikeuchi’s AKIMist®E is the ideal all-in-one solution for industries requiring precise humidity control across a wide range of applications. Its advanced dry fog technology releases ultra-fine droplets that effectively regulate humidity without creating wet surfaces, making it safe to use around sensitive equipment, materials, and production areas. Unlike traditional humidifiers that risk over-saturation and potential water damage, the AKIMist®E disperses a controlled, even mist that reaches optimal levels for each environment—whether for static control in electronics, print stability in commercial facilities, or moisture levels in agricultural setups. With its flexibility and reliability, the AKIMist®E meets the demands of diverse industries, making it a versatile, high-performance solution for comprehensive humidity control.

Article by Industry: Automotive | Controlled Environment Manufacturing | Dry Fog Dust Suppression

Article by Industry: Electronics | ESD Prevention with Dry Fog | Optimal SMT Manufacturing Environment

Articles by Industry: Agriculture | Benefits of Dry Fog in CEA | Greenhouse Humidity Management | Advanced Humidification for Indoor Farming | Optimize Crop Yield | Sustainable Farming