Spray Nozzles Cut Sanitizer Consumption by 70% in Seafood Processing

Solutions or Products Featured

in This Case Study

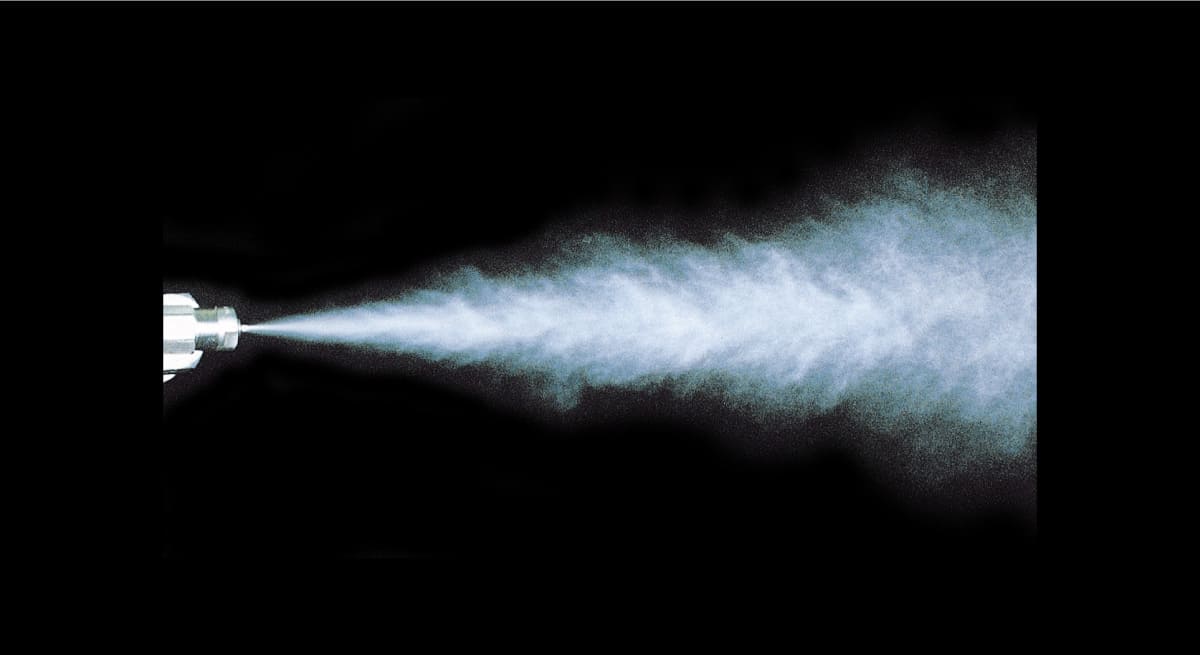

At a carbon material manufacturing plant, self-procured nozzles were used to spray steam and urea solution into exhaust gases for Selective Non-Catalytic Reduction (SNCR)*.

*Selective Non-Catalytic Reduction (SNCR): a process designed to prevent air pollution caused by nitrogen oxides (NOx) by spraying a reducing agent, such as urea solution or ammonia gas, directly into an incinerator without using a catalyst to chemically reduce nitrogen oxides (NOx) to nitrogen (N2) and water (H2O).

However, the nozzles they used at the time produced spray droplets with uneven sizes, causing non-evaporated coarse droplets to adhere to the inner walls of the incinerator. This caused corrosion of refractory materials, such as bricks and mortar. Furthermore, nozzle clogging caused by urea crystallization was also a recurring problem. To resolve these challenges, the plant consulted us for a solution.

First, a test conducted in one of the furnaces demonstrated improvements in the corrosion of bricks and mortar. Additionally, urea solution consumption was reduced by 40%, yielding an annual cost benefit of US$10,000. Furthermore, complete evaporation eliminated drainage, allowing for the efficient use of urea without waste.

Subsequently, based on these results, the implementation of the solution was considered for other furnaces, and a 90-degree bent-type nozzle was also newly adopted.