Automating Brewing Tank Cleaning with 3D Rotating Nozzles to Enhance Efficiency and Safety

Note: The product used in this case is a custom version of the RJ2-PON Series.

Solutions or Products Featured

in This Case Study

A tank manufacturer faced challenges in selecting cleaning nozzles for Clean-In-Place (CIP) systems for coffee extraction tanks used in beverage factories.

The coffee extraction process begins by adding coffee grounds into the tank, followed by gradually injecting hot water from the bottom. The hot water continues to be added until it reaches the top of the tank, during which the coffee is extracted.

After extraction, the coffee liquid is drawn through a filter located at the top of the tank to prevent the coffee grounds from mixing with the liquid.

Afterward, the interior of the tank is cleaned. During this process, it is particularly important to remove coffee grounds that tend to accumulate around the filter.

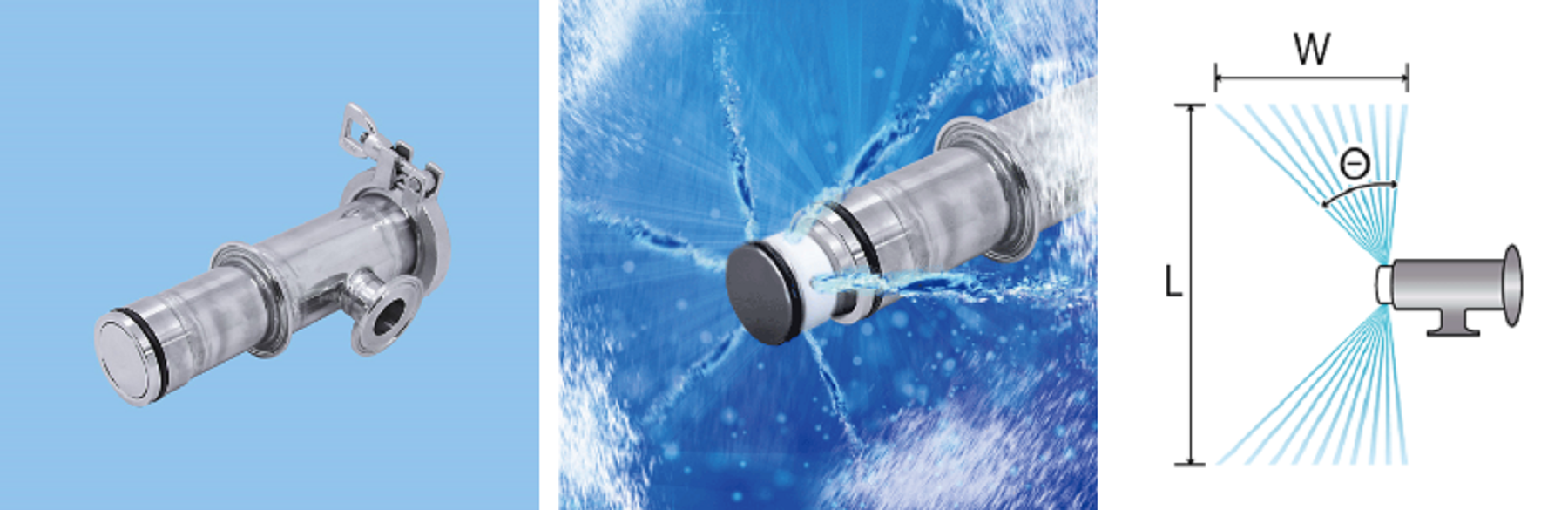

For this reason, the nozzle was installed below the filter and sprayed in a fan-shaped pattern while rotating horizontally, effectively cleaning the entire interior of the tank, including the filter area.

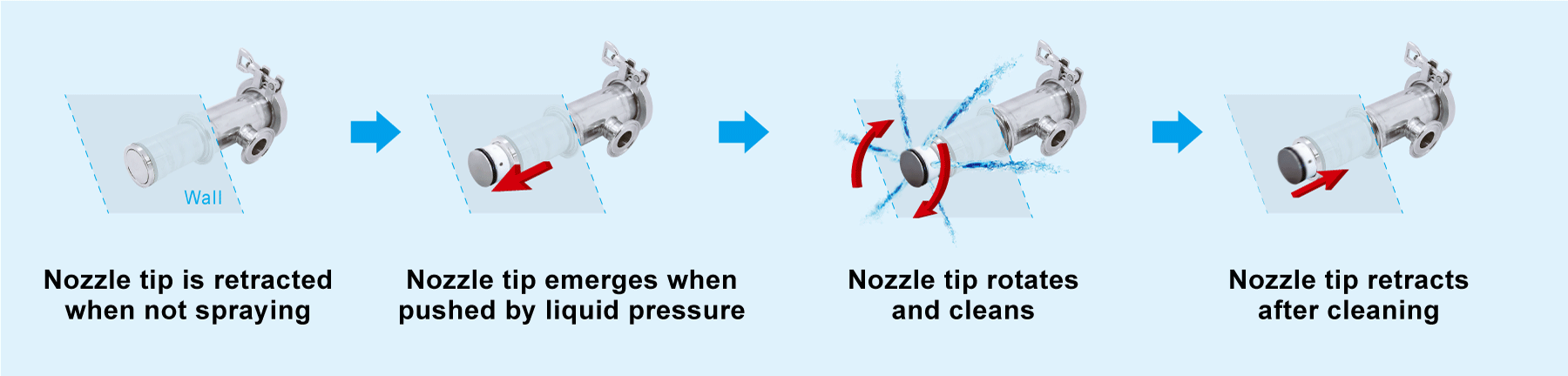

However, since the nozzle was installed below the filter, it remained submerged in the coffee liquid during extraction, leading to the problem of coffee grounds entering the nozzle interior.

As a result, nozzle clogging and rotation failures occurred frequently, requiring the nozzle to be removed from the tank and cleaned up to five times a day during peak periods.

This situation significantly reduced productivity and posed a serious challenge that required an urgent solution.

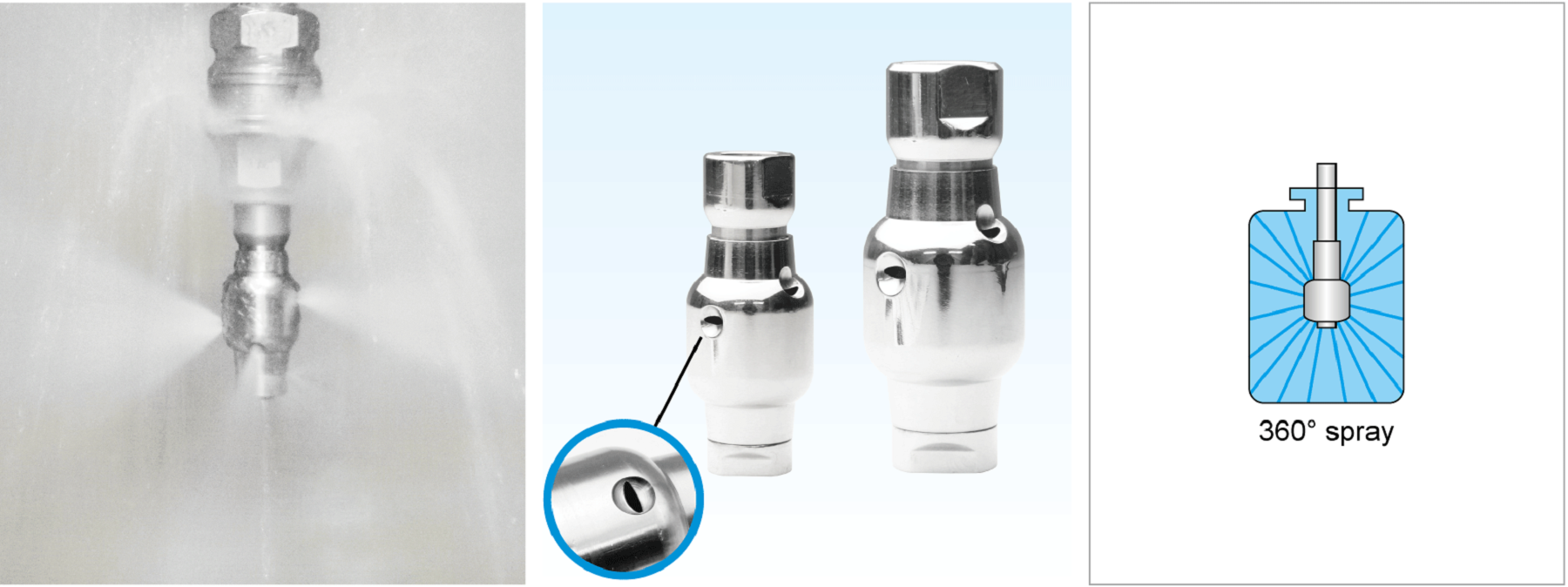

We proposed the pressure-open nozzle RJ2-PON Series.

This tank cleaning nozzle features a design in which the nozzle tip protrudes into the tank interior when activated by the pressure of the cleaning liquid at startup. After cleaning, it automatically retracts, leaving the nozzle tip flush with the tank’s inner wall. This design ensures complete isolation from the cleaning liquid.

In addition to being mounted horizontally on the side of the tank, the nozzle can also be installed vertically by being inserted into the top end plate of the tank, facing downward.

This feature eliminates the risk of coffee grounds entering the nozzle during the extraction process.

The customer purchased one unit for trial use and installed it on an actual tank.

After six months of use, no rotation failures occurred. Following these results, additional units were ordered for mass production, and they have been operating reliably at the beverage factory ever since.