Tire Manufacturing | Odor Control Using Clog-Resistant, Easy-to-Maintain Spray Nozzles

Solutions or Products Featured

in This Case Study

Tires are manufactured by adding various compounding agents to natural and synthetic rubber and processing them through multiple production stages.

The main processes are as follows:

In tire manufacturing, the mixing process is a critical stage that determines the final product quality. How uniformly the rubber and compounding agents are mixed at this stage has a significant impact on all subsequent processes.

This mixing process is performed by the Banbury Mixer.*

*The name “Banbury Mixer” comes from its inventor, Fernley H. Banbury.

Inside a closed chamber, rotors rotate to apply strong mechanical force to the rubber, thoroughly kneading it to evenly disperse the compounding agents.

Banbury Mixer (illustration)

The ability to perform this mixing process stably and with high precision is a key characteristic of the Banbury Mixer.

The Banbury Mixer is a high-performance and indispensable piece of equipment in tire manufacturing plants; however, challenges remain in the mixing process itself.

During mixing, a large amount of heat is generated inside the chamber due to friction between the raw materials and the machine, as well as the intense twisting and folding applied to the rubber.

This heat raises the temperature of the rubber compound, and the accumulated heat within the closed chamber is transferred to the entire unit, increasing the ambient temperature around the mixer.

As the ambient temperature rises, humidity decreases, making the air around the Banbury Mixer increasingly dry. Under such dry conditions, sparks generated from power sections of other equipment or from static electricity can ignite sulfur-containing rubber compounds, posing a real risk of fire.

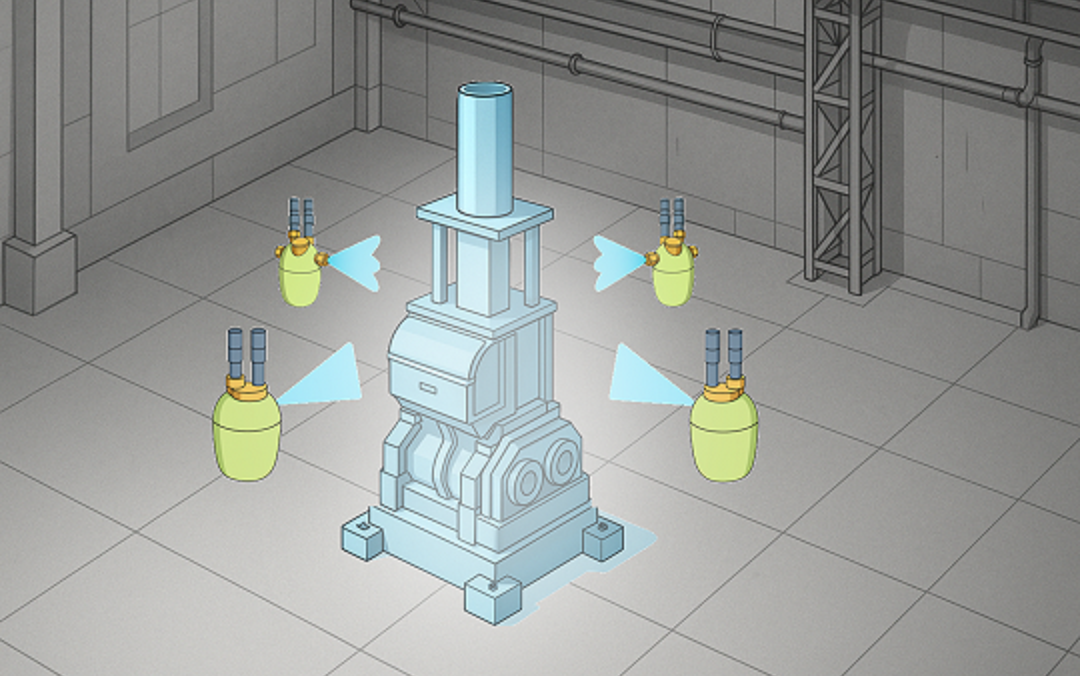

To prevent static discharge and ignition risks caused by low-humidity environments, humidification using IKEUCHI’s Dry Fog Humidifier AKIMist “E” serves as the optimal solution.

The ultra-fine “Dry Fog” generated by the specialized nozzles mounted on the AKIMist “E” quickly evaporates after spraying, adding moisture to the surrounding air. Without wetting equipment or products, each nozzle delivers a powerful spray rate of 2.4 liters per minute.

Whole-factory humidification is unnecessary.

By installing several AKIMist “E” units around the Banbury Mixer and providing localized humidification, effective and efficient ignition prevention can be achieved.

The effectiveness of the Dry Fog humidifier has already been confirmed across multiple tire manufacturers. Within the same manufacturer, installation is steadily expanding to its multiple sites.

IKEUCHI’s products continue to contribute to reliable fire prevention and the maintenance of a safe and secure working environment.