Cold Rolling | Water Removal on Pickling Line: Shorter Air Nozzles Reduce Damage Risk

Solutions or Products Featured

in This Case Study

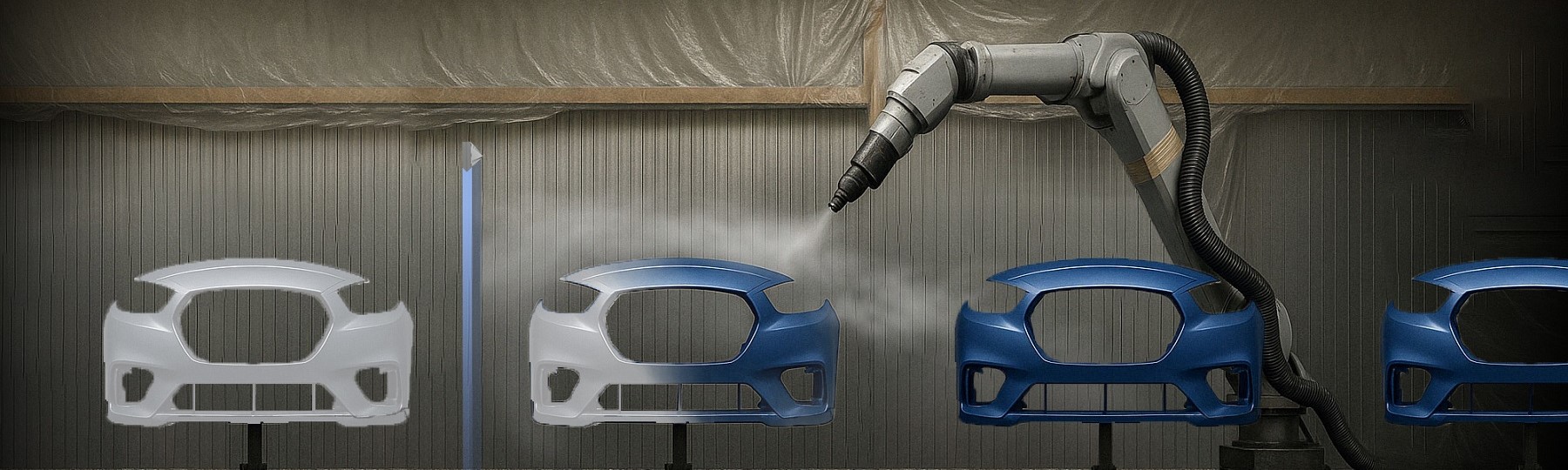

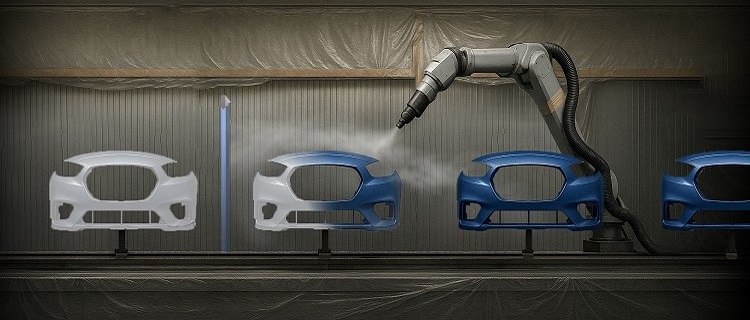

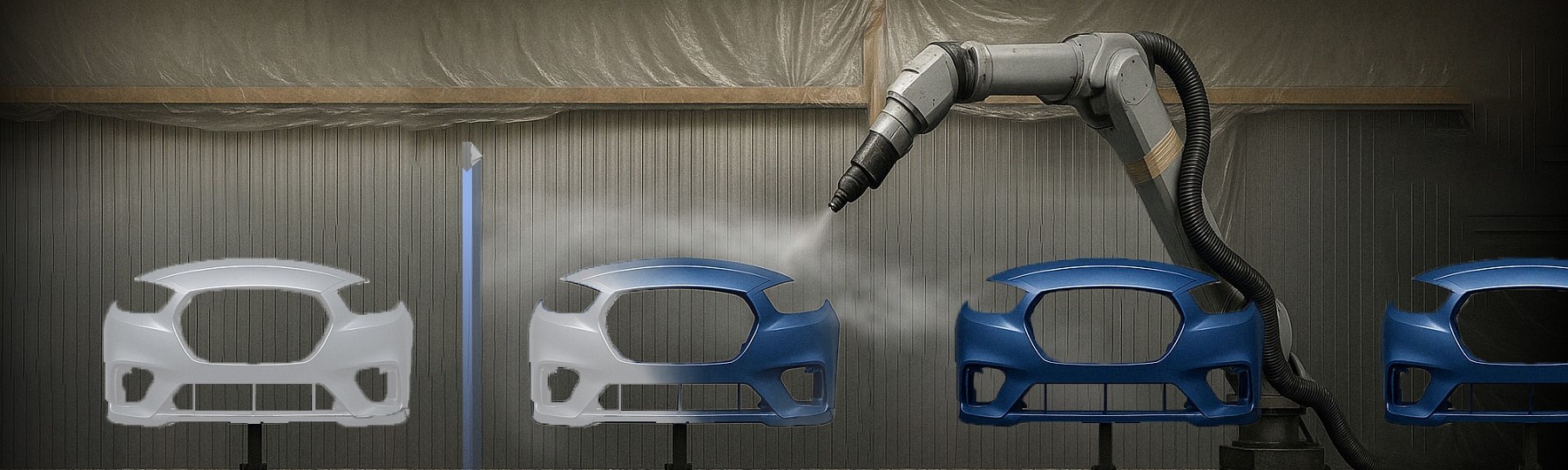

An automotive bumper manufacturing plant was promoting a productivity improvement project.

Without additional investment in existing facilities, the plant began by focusing on increasing the number of bumpers they fed into the painting line to shorten cycle time and raise output.

To achieve this, the spacing between bumpers waiting on the painting line was significantly reduced from 1,500 mm to 500 mm, causing an unexpected problem.

Because the bumpers were now positioned much closer to each other, overspray from the paint-spraying robot reached the next bumper waiting for a different color, contaminating the surface and causing coating defects.

Previously, the spacing between waiting bumpers was 1,500 mm.

Reducing the spacing to 500 mm resulted in overspray reaching the next bumper awaiting painting.

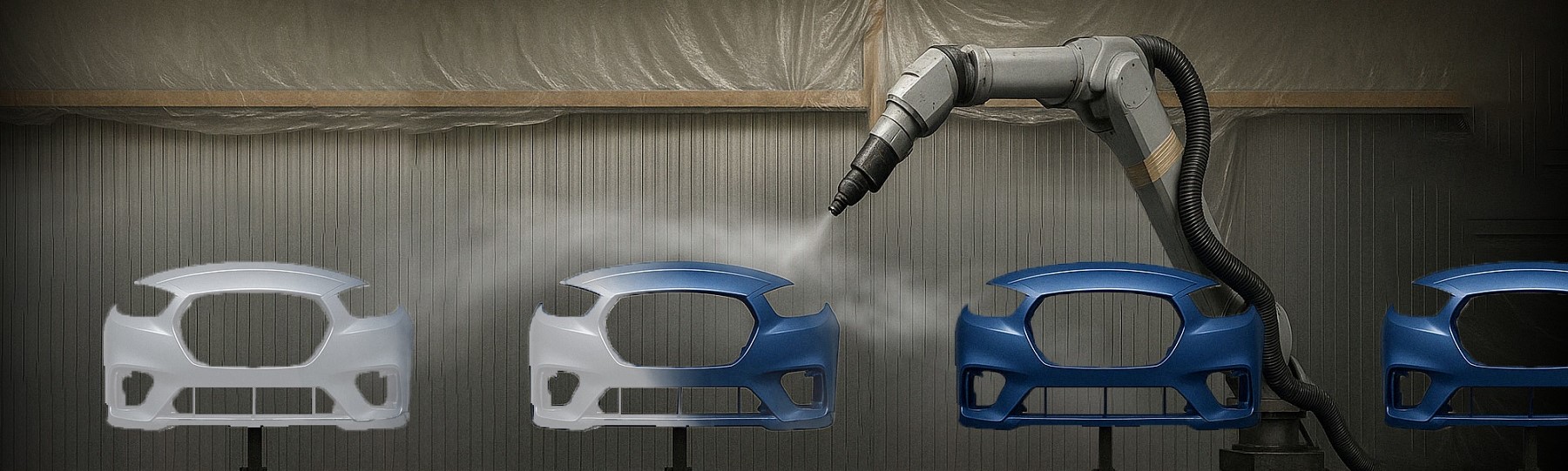

To address this issue, the customer approached IKEUCHI—known for its extensive lineup of air nozzles—to explore measures such as an air curtain to block overspray.

IKEUCHI promptly visited the site to review the painting line and utility conditions.

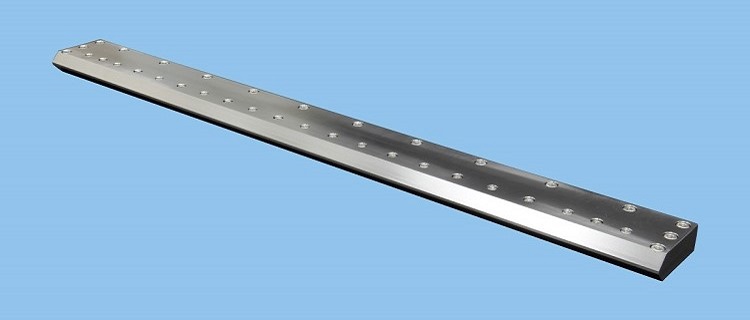

The conveyor was 1,800 mm wide and compressed air was available, so we proposed the SLNHA-H air slit nozzle, specifying a lightweight PVC version for easier installation.

Stainless-steel SLNHA-H shown (reference image). The nozzle used in this case is PVC.

Also known as an air knife, the slit nozzle discharges a laminar sheet of air through a 0.1 mm slit opening.

A custom-made nozzle with a 1,800 mm slit length, matching the conveyor width, was installed at a height that would not interfere with the bumpers and directed straight downward to create an air curtain.

This configuration was proposed as an effective way to block overspray.

The slit nozzle forms an air curtain that blocks the dispersion of paint mist.

The slit nozzle successfully blocked paint mist dispersion as intended, enabling the customer to increase the number of bumpers fed into the painting line.

IKEUCHI’s nozzles continue to support customers in boosting productivity and maintaining consistent coating quality on the production floor.