Automating Brewing Tank Cleaning with 3D Rotating Nozzles to Enhance Efficiency and Safety

Solutions or Products Featured

in This Case Study

A Japanese sake brewery faced challenges in cleaning conveyors after the rice steaming process.

After transporting freshly steamed rice via stainless steel mesh conveyors, sticky rice residue would remain on the mesh. Conventional water rinsing was ineffective in removing these residues, making manual high-pressure washing unavoidable.

As Koji* preparation occurs daily, the steamed rice process also runs without pause. Cleaning the conveyors after each cycle took approximately 30 minutes per unit—totaling one hour for two units—creating a constant labor burden. To address this, the customer approached IKEUCHI for a more efficient solution.

*Koji: steamed rice inoculated with a mold (Aspergillus oryzae), used as a fermentation starter in sake brewing.

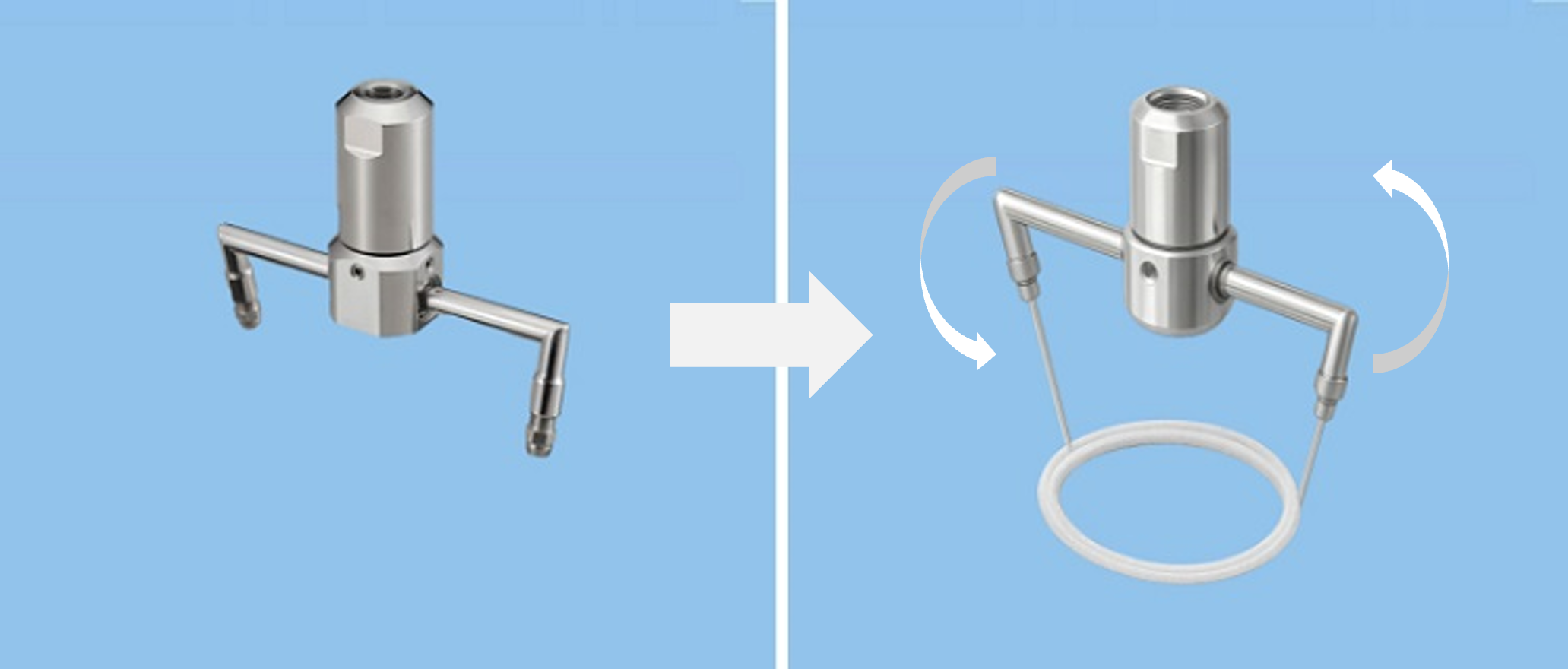

IKEUCHI proposed the JA2 Series rotating nozzle, designed specifically for conveyor cleaning applications.

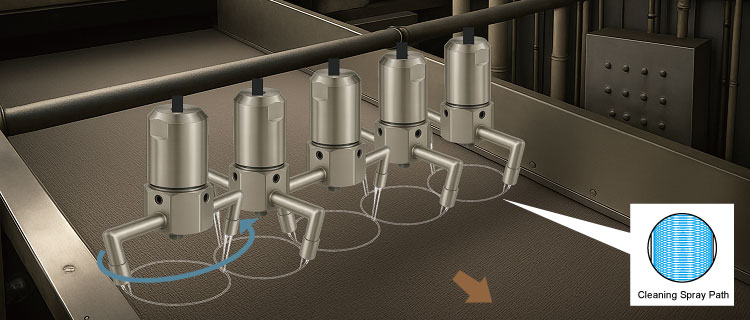

This nozzle rotates horizontally, delivering a concentrated water jet downward from its arms. As the conveyor moves beneath the fixed nozzle, the continuous spray provides a scrubbing action that effectively removes debris lodged in the mesh.

Driven solely by water pressure, the JA2 nozzle requires no external power. Cleaning is initiated simply by activating a pump and opening a valve—enabling fully automated operation.

Illustration of multiple JA2 rotating nozzles installed above a conveyor, showing cleaning spray paths

Automating the conveyor cleaning process significantly reduced manual labor and cleaning time.

The freed-up time allowed staff to focus on other critical tasks, improving overall efficiency and operational flexibility across the site.