Cold Rolling | Water Removal on Pickling Line: Shorter Air Nozzles Reduce Damage Risk

Solutions or Products Featured

in This Case Study

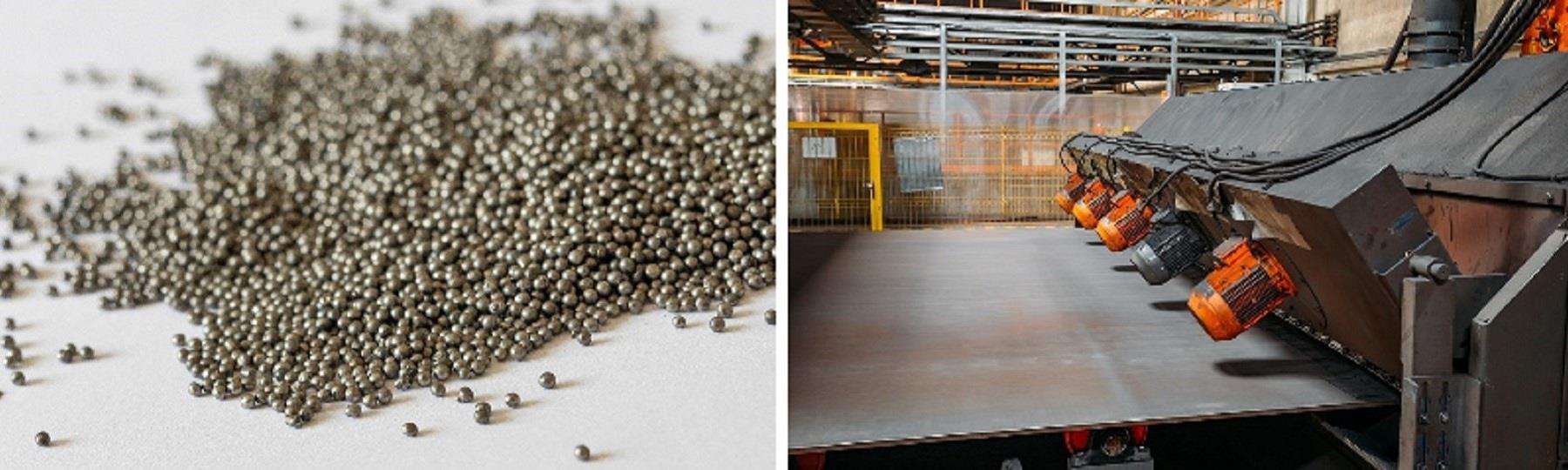

Seismic isolation rubber is a critical component in isolation systems, absorbing and mitigating earthquake vibrations in buildings and bridges.

It consists of alternating layers of disk-shaped rubber and stainless steel plates, encased around the perimeter with protective rubber. This structure provides horizontal flexibility while maintaining sufficient vertical load-bearing capacity, thereby reducing seismic shocks and damage to buildings and equipment.

Before lamination, stainless steel plates undergo shot blasting.

This process propels abrasive media onto the surface to create a fine texture, enhancing adhesion with the rubber.

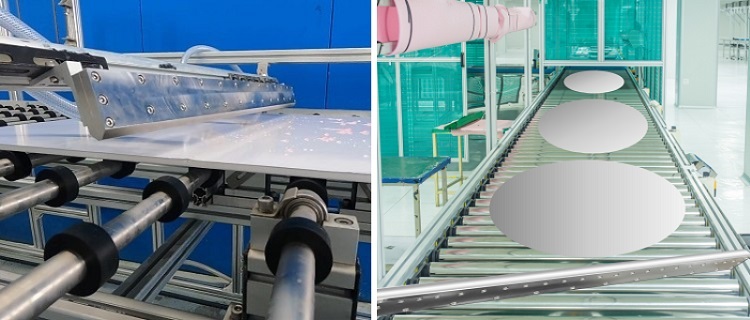

Operators at a seismic isolation rubber manufacturing plant manually removed residual abrasive from the surfaces of shot-blasted stainless steel plates conveyed on roller lines using air blow guns.

However, this air blowing scattered shot debris across the floor, creating a persistent cleaning burden. Seeking a more efficient method to replace manual air blowing, the customer consulted us for a solution.

We proposed a slit air nozzle that ejects a thin, sheet-like stream of air through a slit-shaped orifice.

This type of nozzle, also referred to as an air knife or slit nozzle, sweeps shot debris off the plate surfaces rather than simply blowing it away, enabling effective removal.

Installing the nozzle across the conveyor belt with an offset angle (a slight horizontal angle) toward the left or right edge sweeps shot debris to one side, discharging it at a designated collection point.

Installed across the line width with the nozzle angled to the left