Lubricant Spraying in Press Forming | Ultra-Low Pulse Control for Reduced Consumption

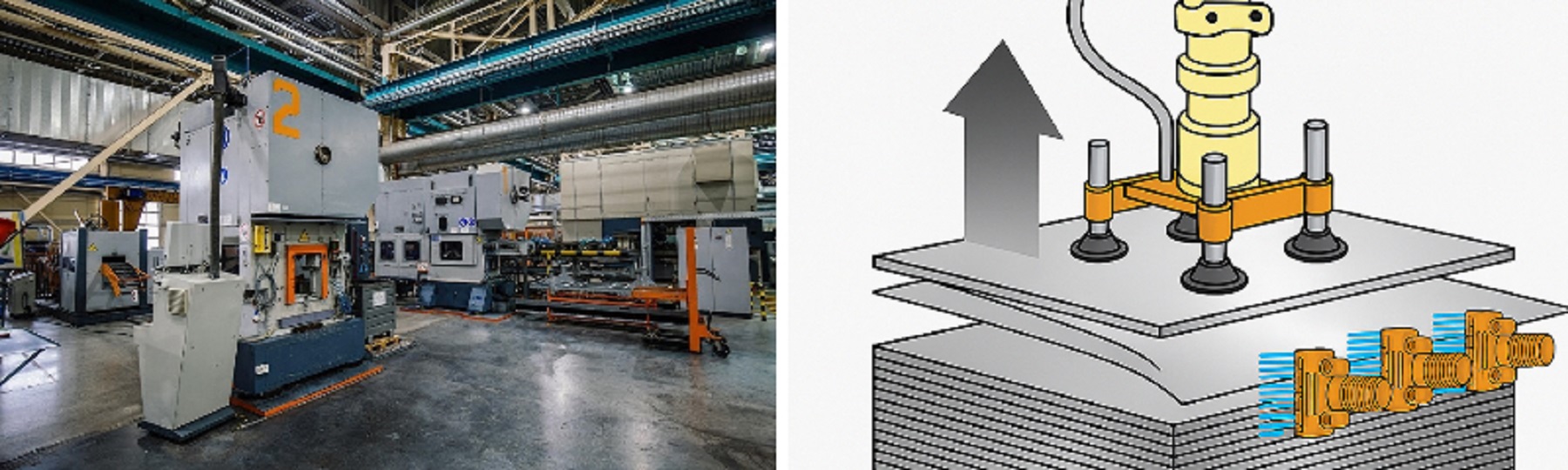

A blank destacker (sheet destacker) is a system that separates stacked blanks/sheets of steel or aluminum and feeds them one by one into the press line. It is widely used in automotive plants to automate blank supply.

The mechanism lifts each blank from the top of the stack using vacuum cups. However, residual oil and other surface contaminants can cause blanks to remain stuck together, leading to multiple blanks being lifted at once. Feeding more than one blank into the press line can result in line stoppages and equipment damage. Preventing these problems is therefore essential.

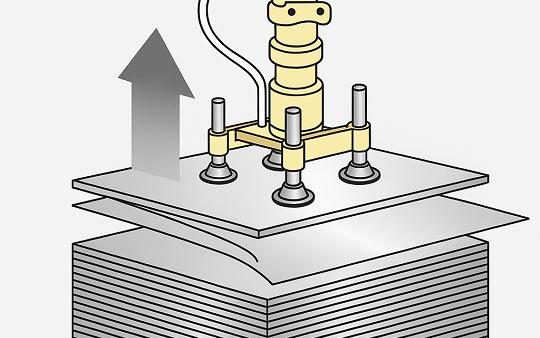

An effective measure is the use of air blow to separate the blanks. By injecting air between them, the stuck blanks are released so that each one can be fed smoothly and reliably.

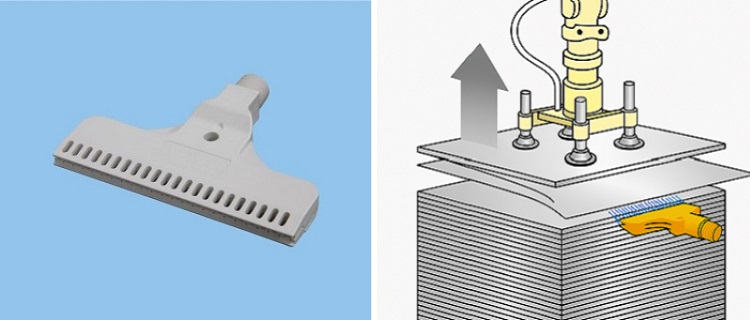

One of the most effective methods is to install elongated air nozzles across the blank width to blow air horizontally. The illustration below shows an example of this approach.

121 mm-wide air nozzle

However, with horizontal air blow, variations in blank thickness can shift gap positions between blanks, sometimes preventing proper separation.

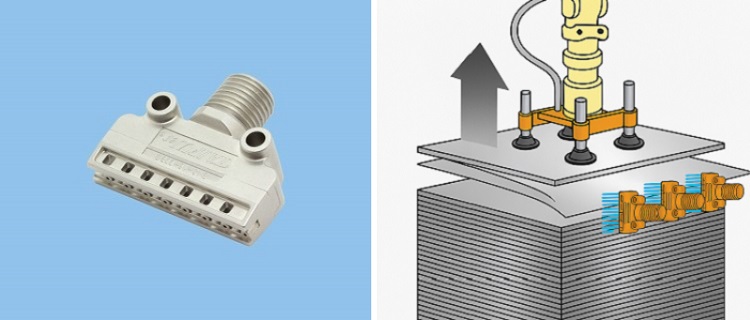

To address this challenge, IKEUCHI proposes arranging multiple narrow air nozzles vertically along the blank width. This configuration ensures stable air-blow performance regardless of gap position.

42 mm-wide air nozzle

IKEUCHI’s nozzles continue to support the stable operation of blank destackers every day.