Eliminating Cleaning Blind Spots on Sanitary Tank Heads with Shower Ball Nozzles

Note: The product used in this case is a custom version of the SWB Series, as detailed in the following article.

Solutions or Products Featured

in This Case Study

A manufacturer of purified water generation systems for pharmaceutical factories was facing challenges with nozzles for cleaning purified water storage tanks.

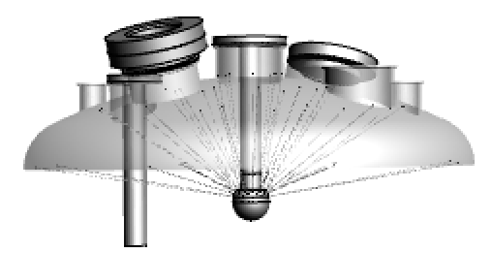

For general tank cleaning, 2D or 3D rotating nozzles are widely used to thoroughly clean tank interior surfaces. However, in tanks handling pharmaceutical-grade purified or ultrapure water, rotating nozzles are generally avoided due to the risk of contamination arising from moving parts.

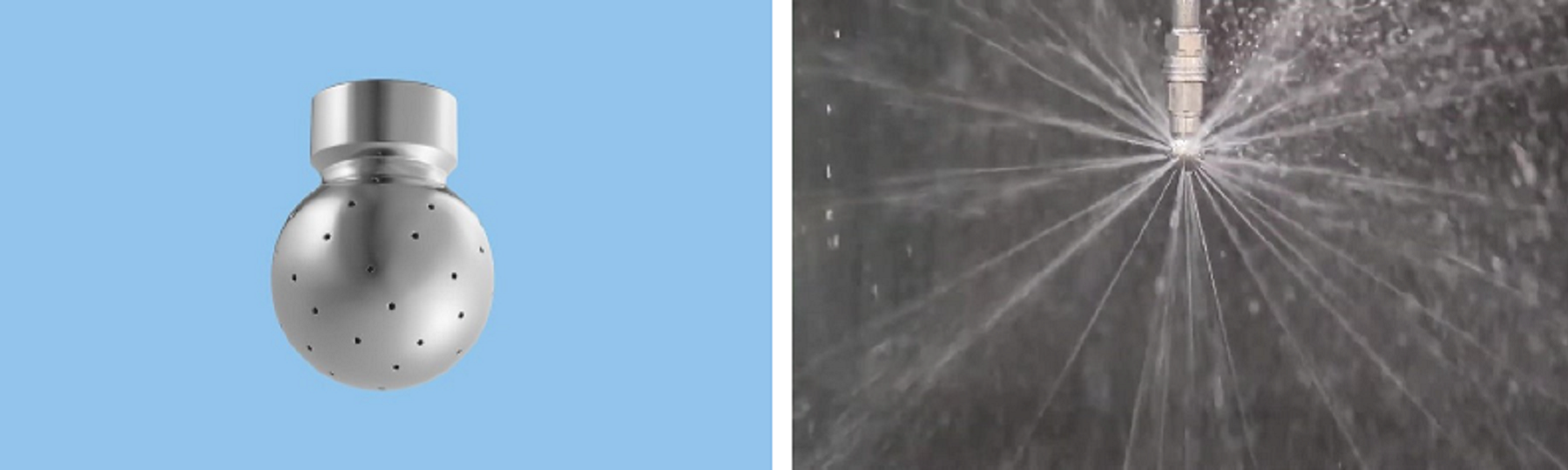

As an alternative, “shower balls” were used. These fixed, ball-shaped nozzles feature multiple holes on their surface that emit solid streams in a shower pattern for cleaning.

Despite this, the design had a weakness: it created blind spots in the upward spray direction, leaving areas that couldn’t be thoroughly cleaned.

To overcome this, two shower balls were installed to cover each other’s blind spots. However, this approach resulted in increased costs for the nozzles and piping design, as well as higher labor requirements for installation and maintenance, leaving the challenges unresolved.

Seeking a solution, the customer consulted IKEUCHI to narrow the blind spots in the upward spray direction and effectively clean the inner surface of the upper tank head, where mounting holes for piping, filters, and instruments are located.

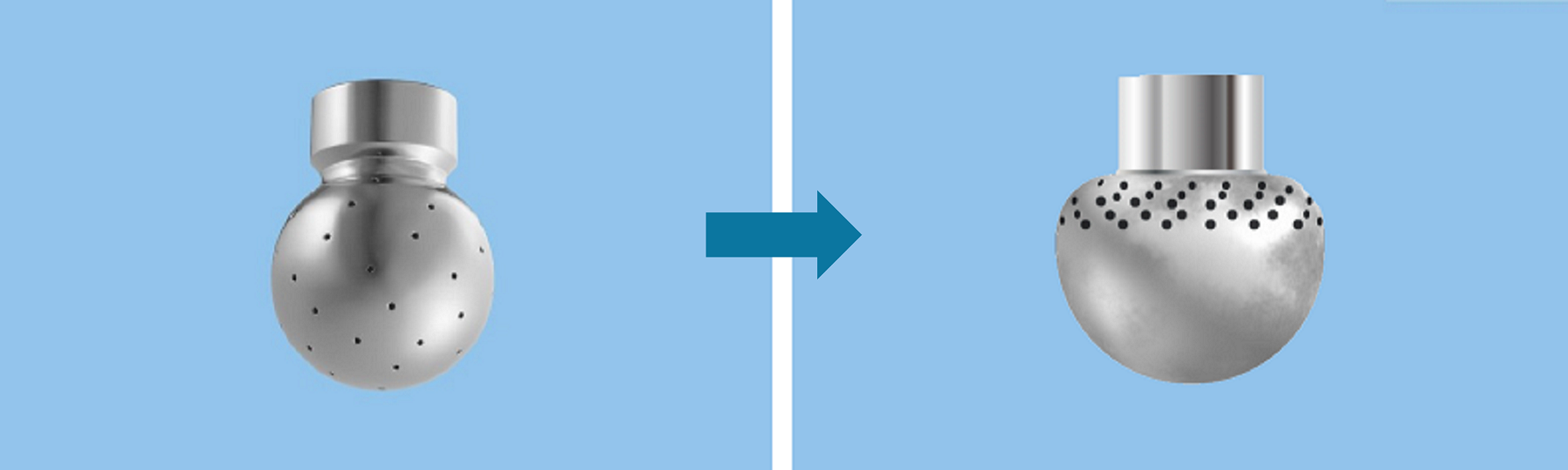

We proposed replacing the conventional spherical shower ball with an oval-shaped design to reduce the blind spots in the upward spray direction. This involved developing a new mold, enabling faster production for future orders.

Spherical Shower Ball to Oval Shower Ball

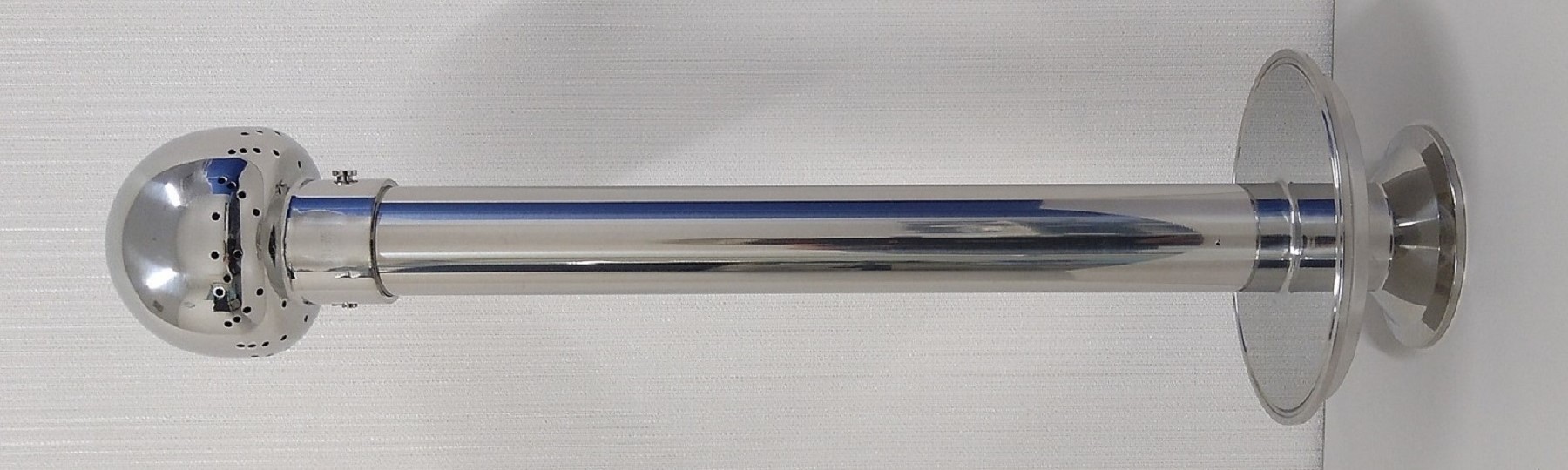

Complete Assembly

Additionally, we created an upward spray trajectory diagram to visualize the cleaning performance, which helped reassure the customer.