Reducing Maintenance Burden in Steel Sheet Surface Treatment with Self-Cleaning Spray Headers

Solutions or Products Featured

in This Case Study

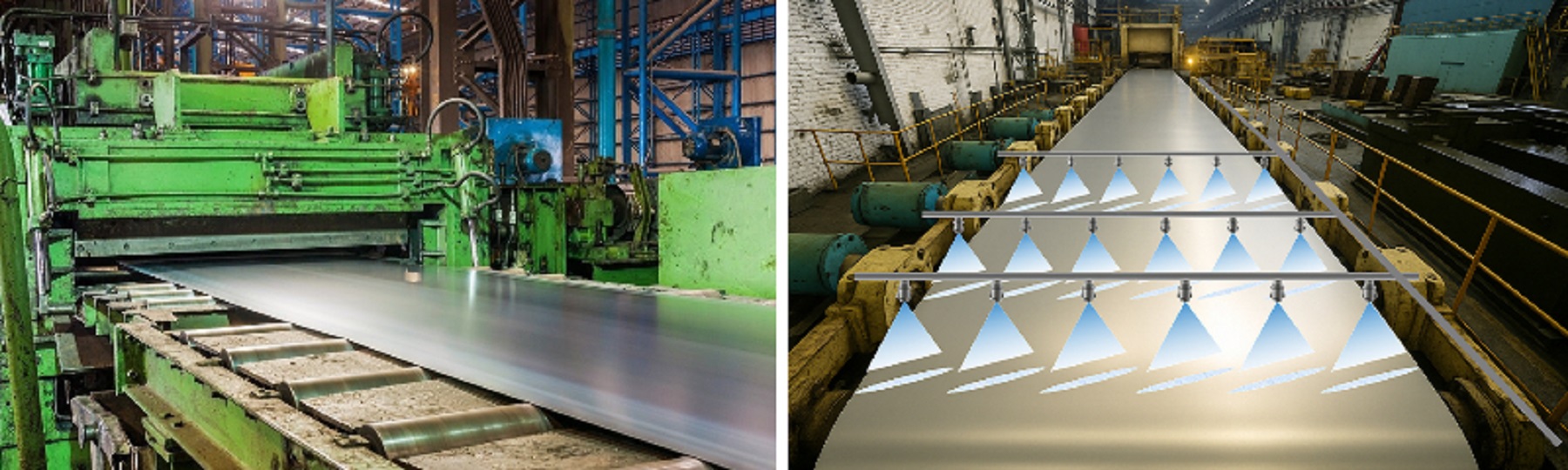

Surface treatment processes for cold-rolled steel sheets—such as pickling, alkaline degreasing, and rinsing—require flat spray nozzles that generate a fan-shaped spray pattern, covering a wide area of a moving workpiece and making them indispensable in these operations.

Stainless steel flat spray nozzle

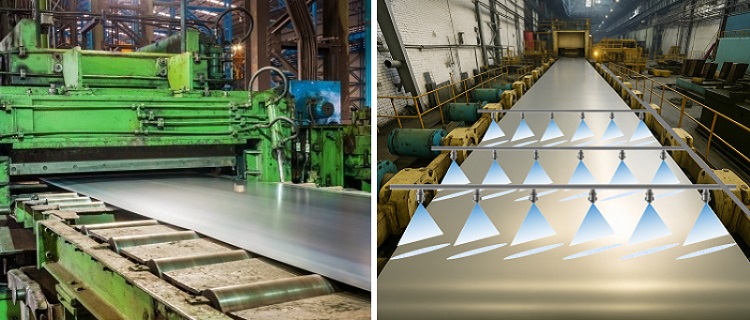

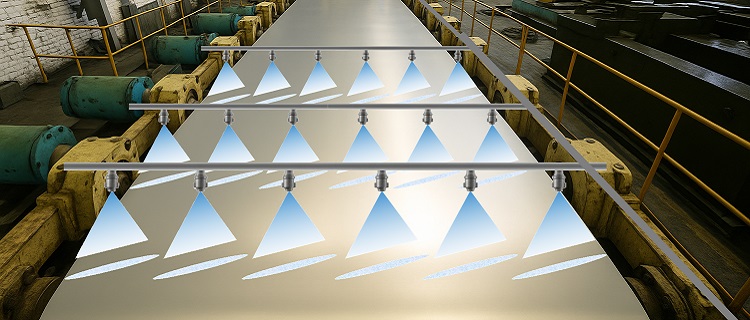

Because sheet widths can reach about two meters, multiple nozzles are mounted on a header with a twist angle (offset angle*) rather than aligned horizontally across the width, where overlapping the edges of adjacent spray patterns produces a uniform distribution across the entire surface.

*For more details on offset angle adjustment, please refer to the following FAQ:

How can I achieve an even spray flow rate distribution with multiple nozzles?

Flat spray nozzles mounted on a header with a twist (offset) angle

These processes rely on a large number of the flat spray nozzles, whose performance directly dictates the quality of steel sheets. Yet the recirculated water used for rinsing carries impurities and foreign matter into the nozzles, causing frequent clogging and degrading their performance.

This necessitates scheduled maintenance that involves removing entire headers, detaching nozzles for cleaning or replacement, and readjusting offset angles upon reinstallation—a time-consuming and labor-intensive process for on-site operators.

To address this challenge, IKEUCHI introduces the stainless-steel flat spray nozzle INVV-SS Series, a newly launched product.

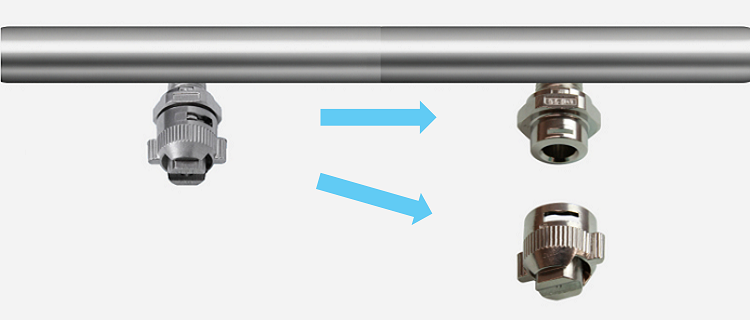

The INVV-SS features a detachable nozzle-tip section consisting of a nozzle tip, cap, and packing. This section can be removed and replaced independently, while the nozzle adaptor remains fixed to the header.

This design eliminates the need to remove entire nozzles from the header during maintenance. Operators can replace only the nozzle tip at clogged locations, or exchange all tips at once and clean them later in a safe area for reuse as spares.

In either case, no readjustment of offset angles on the adaptors is required, significantly reducing on-site maintenance workload.

Left: Adaptor + Nozzle Tip Assembly | Right: Nozzle tip detachable while Adaptor remains fixed to the header

The customer immediately grasped the advantage, remarking that the design would greatly reduce maintenance effort. Convinced by its effectiveness, they promptly decided to adopt the INVV-SS.

With the introduction of the INVV-SS, entire headers no longer need to be removed during scheduled maintenance; replacing only the nozzle tips is sufficient. This change greatly reduces maintenance time as well as labor and cost. In addition, eliminating the need to readjust the offset angle further lightens the burden on site operations.

IKEUCHI spray nozzles continue to support stable surface treatment of steel sheets, contributing to reliable production and high-quality manufacturing.

Note: Although this demonstration mainly features a plastic quick-detach nozzle, the mechanism and maintenance benefits are similar to those of the stainless-steel INVV-SS introduced in this case study. (The INVV-SS appears briefly at 4:56.)

Self-cleaning spray header with built-in brushes: BRASIKan