Enhancing Fire Protection with Foam Spray Nozzles in Waste Treatment Facilities

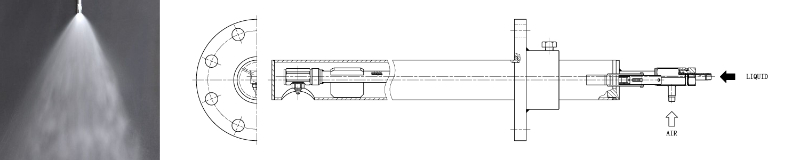

A tire manufacturing plant had been spraying a deodorizing agent inside its exhaust duct using spray nozzles.

Effectively addressing odors specific to tires and rubber requires adequate ventilation through well-installed exhaust ducts and the targeted spraying of a deodorizing liquid.

This approach not only improves the working environment but also helps mitigate concerns about odor complaints from nearby residents.

However, the plant was experiencing frequent nozzle clogging, resulting in a heavy maintenance burden.

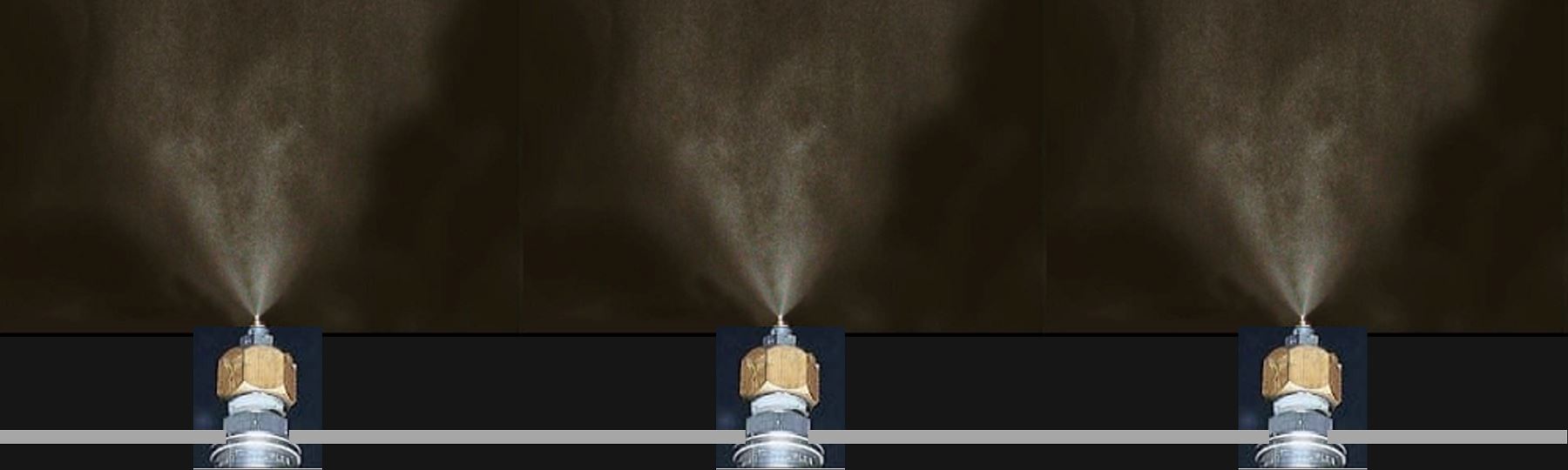

At each spraying location, they had connected three to four relatively low-flow nozzles using tubing to apply the deodorizing liquid.

However, exposure to exhaust in the duct caused foreign matter to accumulate on the nozzles, leading to repeated clogging.

In addition, having multiple small nozzles at each location made maintenance and replacement difficult, leaving them virtually abandoned.

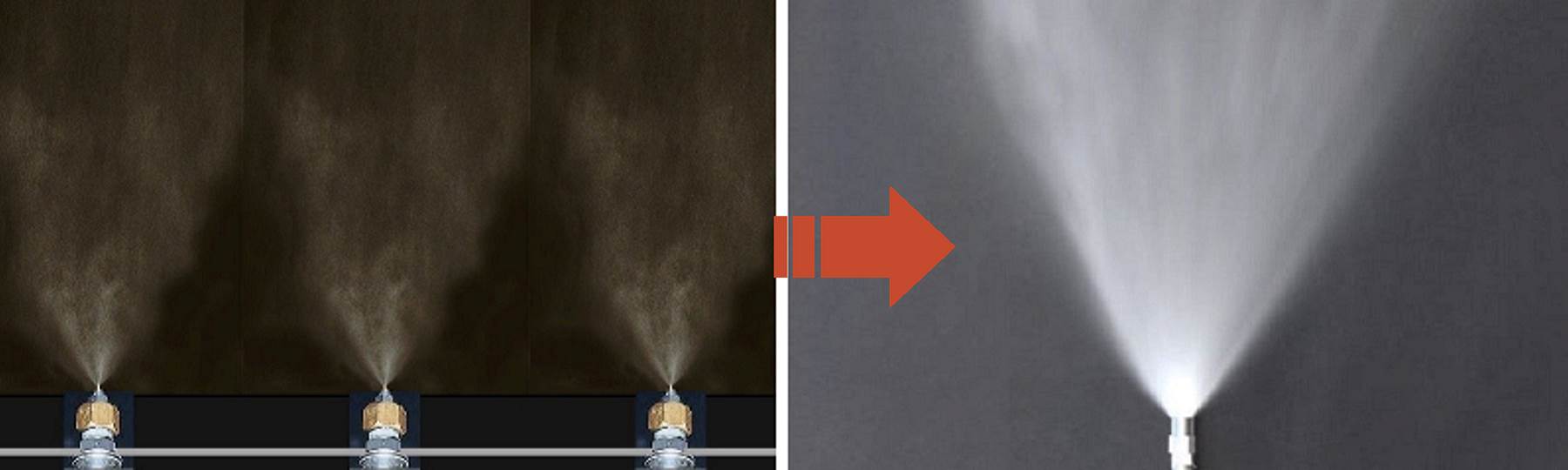

IKEUCHI proposed replacing the original setup of three to four small nozzles with a single high-flow nozzle. Increasing the flow rate allows for a wider liquid passage within the nozzle, reducing the chance of foreign matter adhering and thereby helping to prevent clogging.

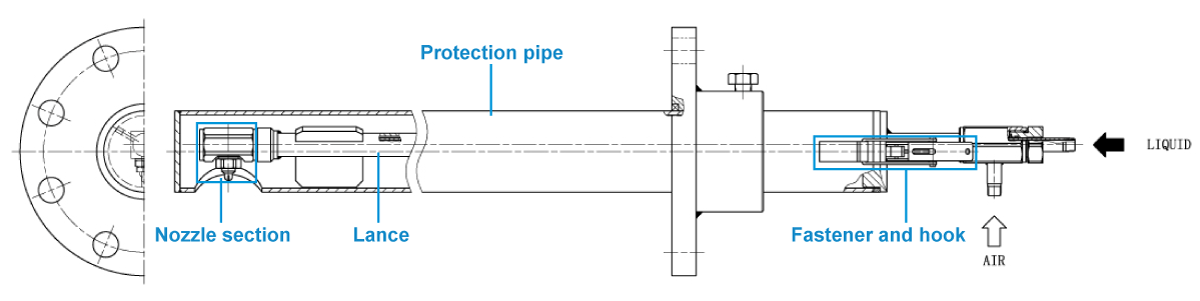

In addition, IKEUCHI incorporated a design that enclosed the nozzle and lance (combined fluid and air supply pipe) inside a protective pipe with a fastener, and delivered it as a unit that facilitates nozzle insertion and retraction during maintenance tasks.

The protection pipe also helps prevent foreign matter from adhering to the nozzle, contributing to reduced clogging.

As featured in this case study, IKEUCHI provides optimized solutions tailored to each customer’s production line, operating conditions, and on-site needs— whether you’re aiming to improve the working environment, increase productivity, or stabilize product quality.

Let us help you solve your challenges with the power of precision spraying!