Preventing Condensation and Clinker Build-Up in Exhaust Gas Cooling at Incineration Facilities

Solutions or Products Featured

in This Case Study

A cement plant was using a rotary dryer to dry limestone, but was experiencing performance issues with the spray nozzles used in the dryer’s emergency water-spray system.

The dryer is operated with a system that recovers and reuses the heat generated during operation. In an emergency shutdown, the heat-recovery cycle stops and the internal temperature rises excessively, so water must be sprayed through the nozzles to cool the dryer.

However, the originally installed nozzles caused excessive wetting inside and around the dryer during spraying.

The original nozzle supplier could no longer be identified, making it difficult to order replacements or find a suitable alternative. As a result, the customer consulted IKEUCHI, a specialist in industrial spray nozzles.

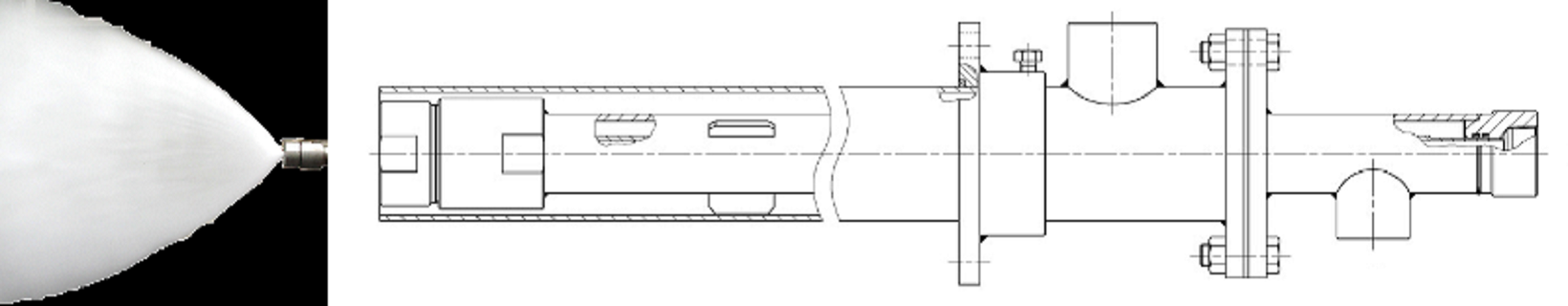

After visiting the site and confirming the nozzle type, required spray rate, and equipment specifications, IKEUCHI determined that its spillback nozzle*1—the GSPB nozzle*2—was the most suitable option.

*1A spillback nozzle (also called a return-flow nozzle) is a spray nozzle that allows the spray capacity to be adjusted by opening or closing a return flow valve while keeping the supply pressure constant. It features minimal variation in droplet size even when the spray rate is increased or decreased. In the standard SPB series, the largest model delivers 30 L/min at a supply pressure of 0.2 MPa.

Learn more about the SPB Series

*2 The GSPB Series is a higher-capacity version of the SPB series, with a maximum spray rate of 167 L/min (10 t/h). This enables optimal cooling inside a rotary dryer with an inner diameter of 5 m and a length of over 30 m—without causing flooding in the surrounding area.

The rotary dryer had six nozzle ports near the material chute. Because the basis for the customer’s target spray rate was unclear, IKEUCHI proposed installing four nozzles first and adding more only if necessary.

Testing showed that four nozzles provided sufficient cooling performance, reducing cost as well as maintenance effort and expense.

IKEUCHI’s spray nozzles continue to support safe and reliable equipment maintenance.