[PDF] 7 Benefits of Dry Fog Humidification in SMT processes

Solutions or Products Featured

in This Case Study

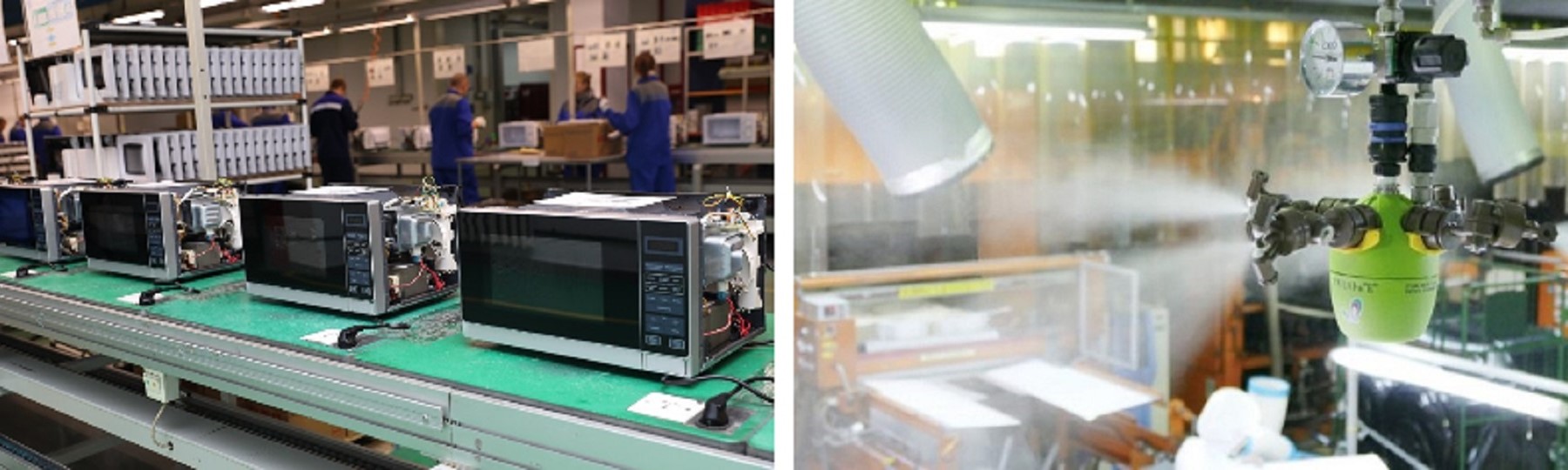

In a kitchen appliance factory, frequent failures in the parts bonding process led to a significant drop in productivity.

In this process, parts with adhesive applied are bonded together, left to cure for a specific period, and then transferred to the next assembly stage. However, failures occurred when parts remained insufficiently bonded or completely unbonded after the curing time, and these defects were not noticed, allowing the parts to pass to the next stage.

As a result, additional inspections were required in the subsequent process, and parts often had to be returned for rework. In the worst-case scenario, the entire lot had to be quarantined for further inspection.

To investigate the cause of the failures, an assessment of the site environment was conducted, revealing that the humidity levels dropped to approximately 30% during the winter months. Furthermore, the adhesive used cures by absorbing moisture from the air, so it became clear that insufficient humidity in the process was the cause of the bonding failures.

Determining that proper humidity control was necessary to resolve the issue, the customer consulted IKEUCHI for a solution.

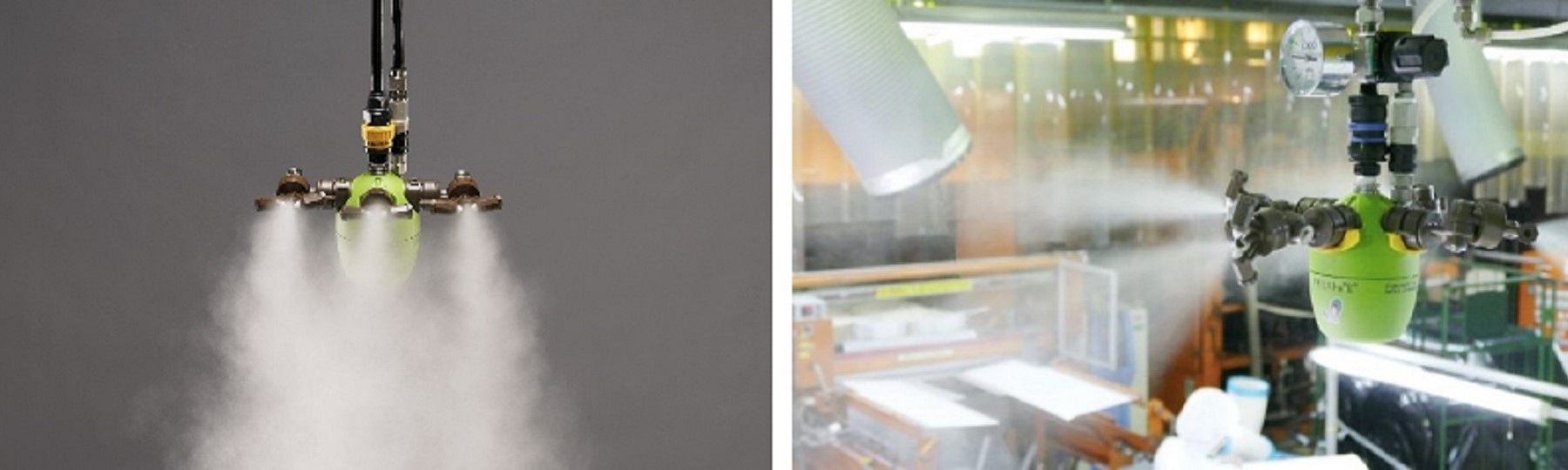

We proposed the implementation of the Dry Fog Humidification System AirAKI. This system integrates the Dry Fog Humidifier AKIMist “E” with a humidity controller and sensor, enabling automated humidity control for the bonding process.

In addition, by using the AE-UT Adaptor to align three Dry Fog spray nozzles on the AKIMist “E” to spray in the same direction, efficient humidification within the space was achieved.

The system raises the humidity in the process to 50% and automatically maintains this level once the target humidity is reached. By creating this controlled humidity environment, the curing of the adhesive in the bonding process is accelerated, resolving issues like insufficient or incomplete bonding and significantly improving work efficiency.