FPD Equipment | Optimizing Etching with High-Precision, Uniform, Responsive Slit Nozzles

Solutions or Products Featured

in This Case Study

The ongoing trend toward miniaturization and enhanced functionality in electronic devices demands increasingly precise wiring patterns for printed circuit boards (PCBs) on which electronic components are mounted.

To meet these market needs, a manufacturer of PCB production equipment was developing systems capable of forming finer patterns. During this process, a key challenge arose: improving the maintenance efficiency of spray nozzles used to apply stripping solutions during the resist stripping process.

Traditionally, polypropylene (PP) nozzles with excellent chemical resistance were used. Featuring a quick-detachable design, they allowed for easy attachment and removal of the nozzle tip by simply turning it, providing exceptional convenience during maintenance tasks such as nozzle replacement.

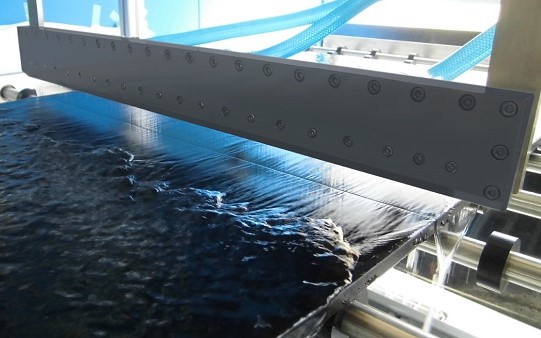

Plastic Quick-Detachable Nozzle (Left) and Stripping Solution Spray Pattern (Right)

However, achieving finer patterning required heating the stripping solution to nearly 100°C.

This posed a challenge, as PP nozzles had a heat resistance limit of 80°C, rendering them unsuitable for the new precision manufacturing equipment.

As an alternative, standard stainless steel nozzles with threaded fittings were considered. However, maintenance would require unscrewing dozens of nozzles, significantly increasing the workload for users.

This prompted the need for a new nozzle that could address both high temperatures and user-friendly maintenance requirements.

To address the customer’s needs, we engineered and crafted a stainless steel nozzle matching the performance of conventional PP nozzles, while designed to spray high-temperature liquids.

Retaining the same excellent ease of maintenance as before, the new quick-detachable nozzle offers superior chemical resistance and is built to withstand temperatures of up to 150°C. This innovation enables the efficient and reliable spraying of high-temperature stripping solutions without any issues.

In addition to higher liquid temperatures, there has also been a trend toward increased spray pressures. This nozzle supports a maximum operating pressure of 2.0 MPa, compared to 0.4 MPa for the PP nozzles, effectively overcoming this challenge as well.

Stainless Steel Quick-Detachable Nozzle (Left) and Stripping Solution Spray Pattern (Right)

With the successful completion of the equipment design adopting the metal quick-detach nozzles, the manufacturer of PCB production equipment can now confidently ship the new systems to PCB manufacturers, knowing that the challenges of high temperatures, increased spray pressure, and ease of maintenance have been fully addressed.