Optimizing Gas Cooling Nozzles for Enhanced Maintainability at Waste Incineration Plants

At a waste incineration facility, exhaust gas cooling was performed using a spillback nozzle from another supplier. However, condensation formed on the cooling tower’s inner walls, leading to clinker* accumulation. This buildup disrupted exhaust gas flow, negatively affecting equipment operation.

The problem stemmed from large spray droplets that failed to fully evaporate. Additionally, the gas flow carried the spray to the tower’s inner walls, where it adhered.

*Clinker: A hard deposit formed when the inner walls of the tower become wet, causing organic matter, metallic elements, mineral particles, or molten substances to accumulate and solidify.

The conventional spillback nozzle from another supplier was a hydraulic nozzle that sprayed water using water pressure alone. In contrast, IKEUCHI developed and proposed the ASPB series, an air-assisted (pneumatic) spillback nozzle that uses compressed air to achieve finer atomization.

Using compressed air, the ASPB series nozzle produces finer droplet sizes compared to the conventional nozzle, effectively resolving the issue of incomplete evaporation. While the Sauter mean droplet diameter of the conventional nozzle was 130 μm, the air-assisted nozzle reduces it to approximately 97 μm.

Additionally, the use of compressed air increased the spray velocity, preventing dispersion and allowing efficient exhaust gas cooling without wetting the inner walls.

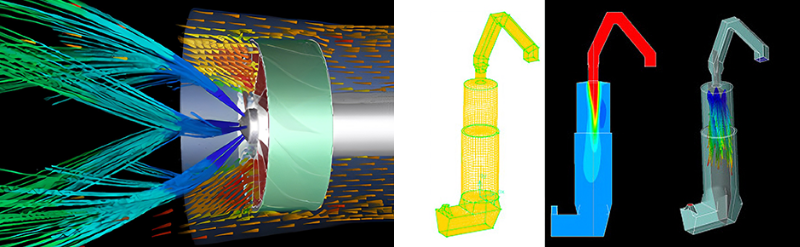

CFD simulation of the cooling tower interior